- Admissions

- Academics

- Research Office

- Student Life

- News & Events

- Outreach

- About

Dr. Mohamed Ibrahim Hassan Ali is an Associate Professor in the Mechanical and Nuclear Engineering Department and the Thermal Theme Lead at the Center for Membrane and Advanced Water Technology (CMAT) at Khalifa University, UAE. He has previously held academic positions as an Associate and Assistant Professor at Helwan University, Egypt, and served as a Senior Research Scientist and Lecturer at the University of Kentucky, USA. Dr. Ali’s academic journey is marked by his pioneering contributions to the fields of hydrogen, hydrocarbons, biofuels, and syngas combustion. His work, which includes developing an extensive database on laminar burning characteristics and flame stability, has been instrumental in advancing both full and reduced reaction mechanisms for these fuels, providing deep insights into their burning rates and stability under different preferential diffusion conditions.

In the energy sector, Dr. Ali has conducted extensive computational fluid dynamics (CFD) studies that have played a crucial role in optimizing and understanding the physical and transport phenomena in various energy systems. His work spans the design of industrial burners and furnaces, improving internal combustion engine performance, utilizing decarbonated fuels like hydrogen and ammonia in HCCI engine, and enhancing waste heat recovery systems. A significant part of his research also focuses on renewable energy, where he developed models to assess the renewability of solar CSP/biofuel gas turbines, semitransparent PV in multifunction windows, utilizing solar energy in membrane distillation system. His contributions to the aluminum and steel industries include the design of waste-to-energy recovery systems that generate electricity, distilled water, and preheat solid scrap within industrial plants. Furthermore, Dr. Ali has investigated power modulation strategies in the aluminum industry to facilitate the integration of renewable energy, reflecting his commitment to enhancing energy efficiency and sustainability in key industrial sectors worldwide.

Dr. Ali’s expertise in water and energy systems is further demonstrated by his work on innovative water desalination and distillation processes. He has developed advanced CFD models to improve water treatment technologies, particularly in membrane systems used for desalination. His research in this area not only optimizes the energy efficiency of desalination processes but also integrates waste heat recovery methods to enhance the overall sustainability of water production. With over 190 published articles in top journals and more than 30 projects as principal or co-investigator, Dr. Ali’s contributions are widely recognized and cited. Notably, in 2002, the U.S. Department of Energy selected him as one of 13 leading scientists to develop an ingot-cracking index aimed at improving energy efficiency in the aluminum industry. His work continues to bridge the gap between conventional and renewable energy systems, with a particular focus on water-energy nexus challenges.

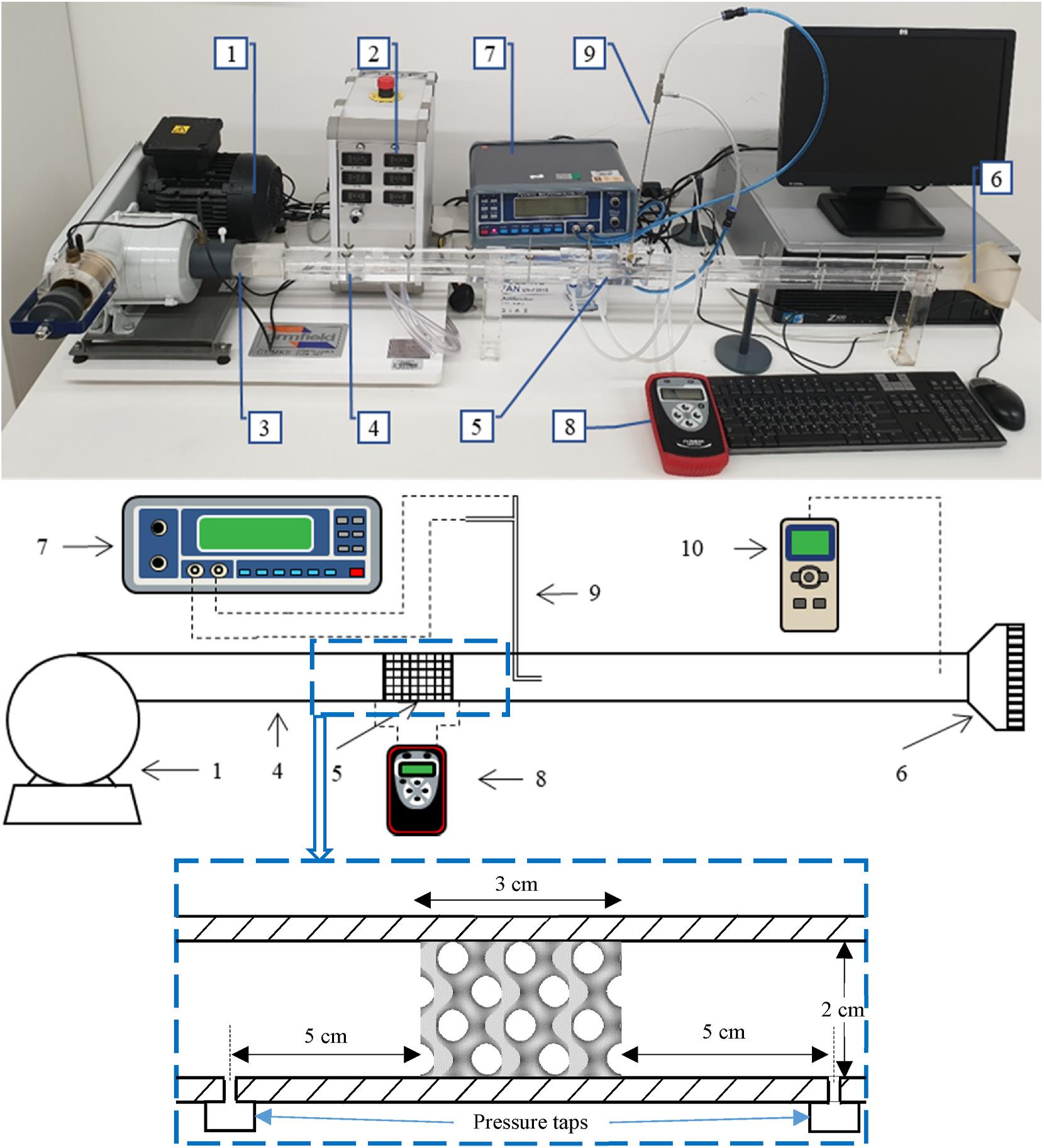

Heat Sinks testing apparatus - This apparatus is developed to test the Triply Periodic Meta Structure TPMS heat sink cooling performance. TPMS is produced using 3-D printing technology.

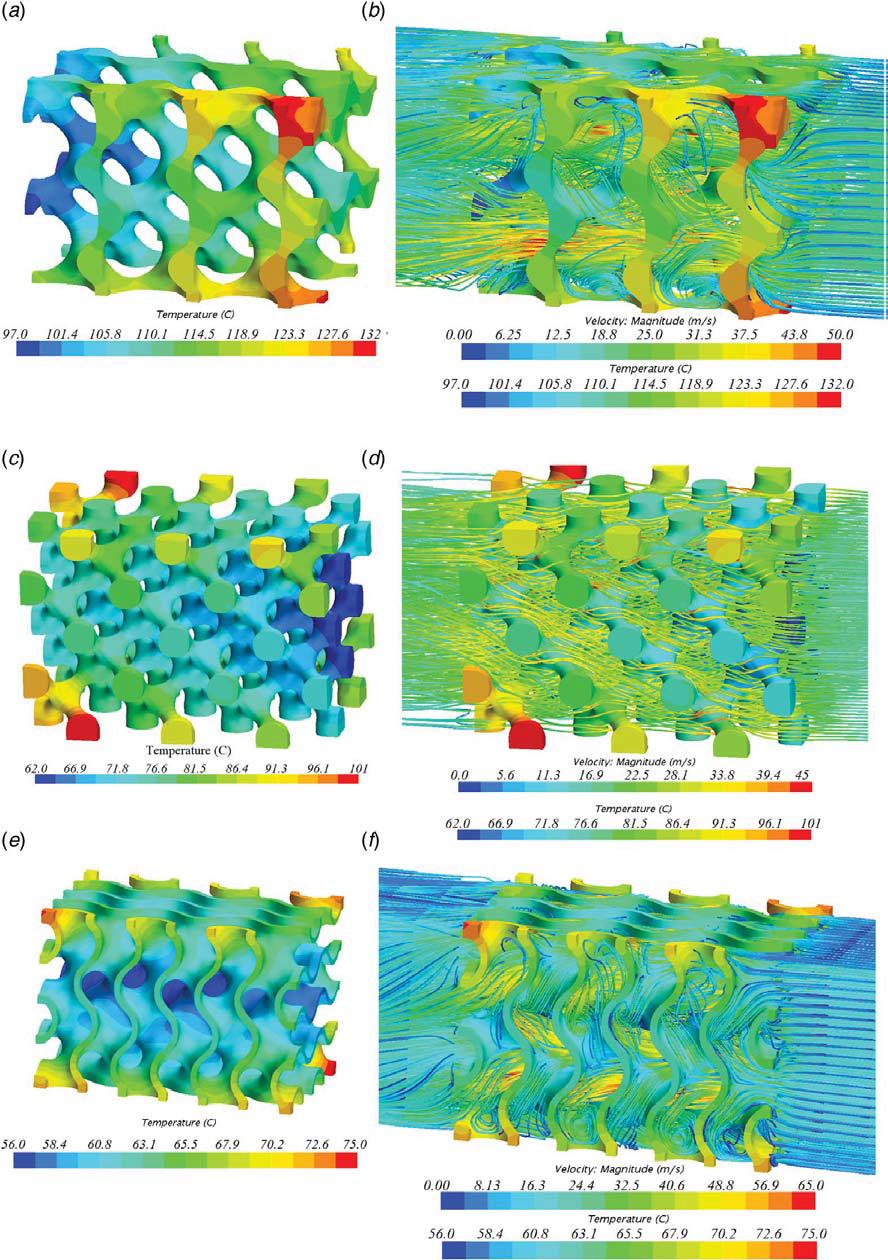

Heat Sinks CFD models - Detailed flow and temperature characterization for heat transfer performance

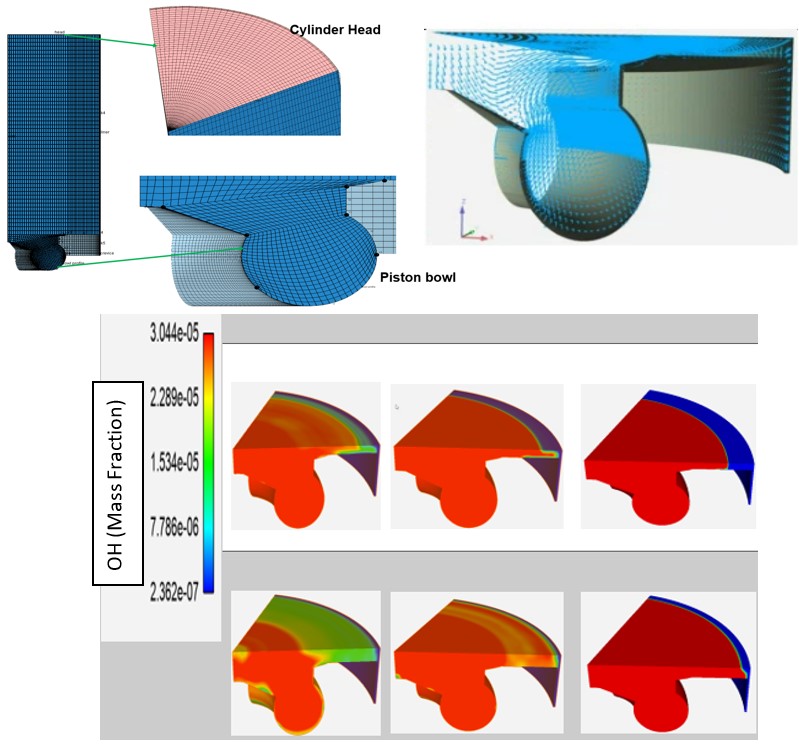

Internal Combustion Engine Simulation - This research focuses on the new engine design for bringing Hydrogen, syngas, and biogas fuels in HCCI engines.

Hilton Combustion Units - This unit is used to combust different types of fuels, including Diesel and BioDiesel fuels to investigate the benefits of biofuels over conventional diesel fuels. Samples of soot formation are collected to study the flame soot characteristics of each fuel.

Title: Variable Refrigerant Flow (VRF) Cooling in Smart Buildings.

VRF systems use refrigerant as the cooling and heating medium, which can be precisely controlled to meet the varying needs of different zones within a building. These systems consist of an outdoor unit and multiple indoor units, with the capability to control the amount of refrigerant flowing to each indoor unit based on demand. Variable refrigerant flow (VRF) systems are a key component of smart building technology, offering enhanced energy efficiency, flexibility, and comfort. When integrated with smart building management systems, VRF systems contribute significantly to the creation of intelligent, responsive, and sustainable buildings.