- Admissions

- Academics

- Research Office

- Student Life

- News & Events

- Outreach

- About

Prof. Isam Janajreh is Professor and the associate chair in the Mechanical Engineering department. He received his Ph.D. from Virginia Tech in Eng. Science and Mech. Specialized in fluid-dynamics, thermochemical-conversion, and solid/fluid interactions. He joined VT as visiting professor at ESM & Math Dept. (1998), and then Michelin US R&D and Michelin France heading European Project ’99-04. He joined Parametric Solutions Inc. in Florida (‘05-‘07) heading numerous US governments projects with GE/Pratt/Rolls. He joined Masdar in 2007 as visiting assistant MIT professor, associate (2010), and currently is full professor. His research focus on reactive flow, conjugate heat and solid fluid interaction applied in various engineering application. Including gasification and reforming, desalination, and energy and sustainability. He established the Waste to Energy Laboratory at Masdar/KU that drew funds from Tadweer, Beeah, ADNOC, Ducab, NIST, Sonkeyenergy, Masdar Corp. and several internal MI grants and numerous others. He authored over 140 refereed publications and graduated 27 MS and Ph.D students. Isam is a regular reviewer of EC&M, Appl. Pyrolysis, Ren. Energy, Fuel, Appl. energy, member of ASME, TS&T, Rubber Division, ASCE, and several scientific committees. Isam is also Editor in chief, associate editor, and editor for Int. J. of Enhanced Research in Science, Tech. & Eng., IJTEE, J. of Energy and Power Eng. Solid, J. of Solid Waste Tech. and Management.

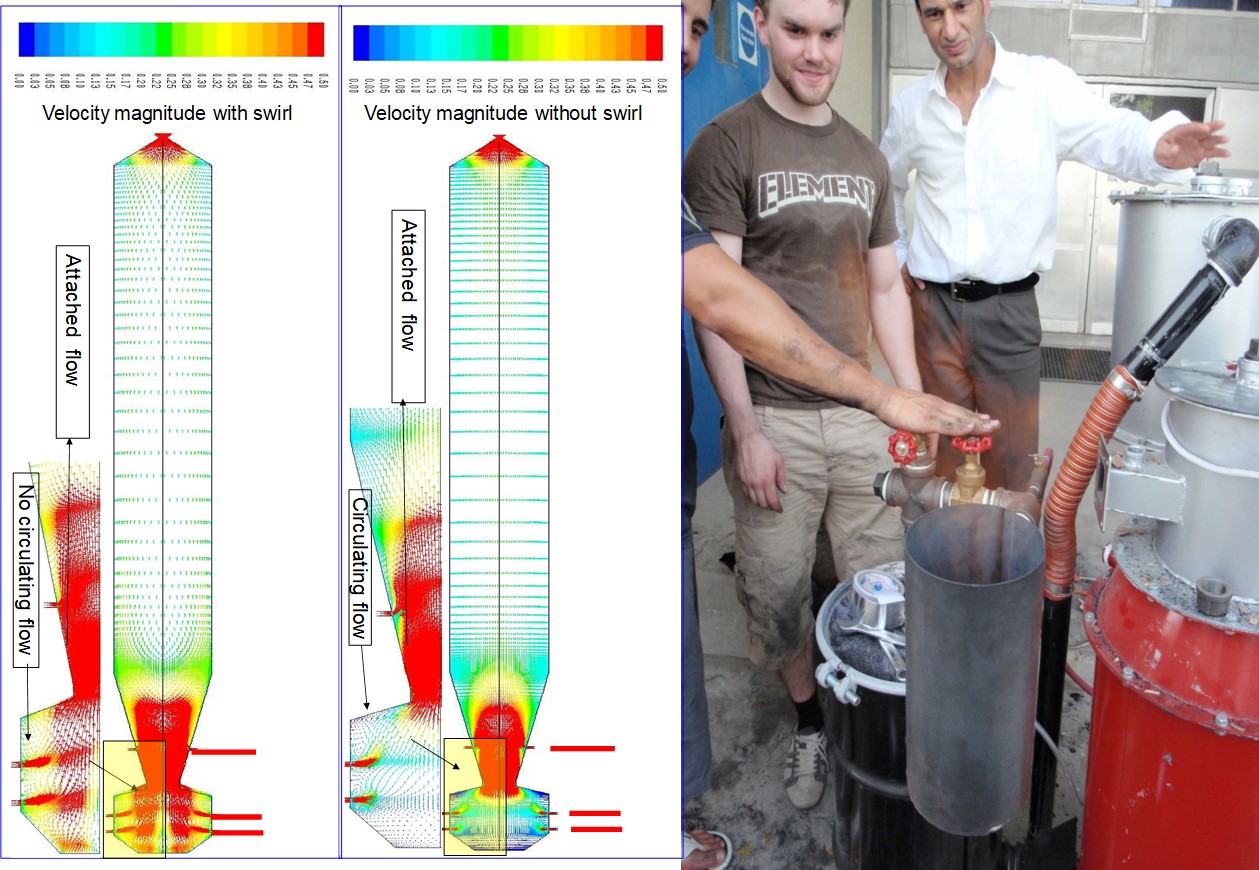

Gasification of Different Waste Streams: Including MSW, Plastics, tire Shreds, Spent pot lining, Shale Oil: This project involves conducting TGA analysis to capture the thermal decomposition of the feedstock and accordingly inferring their proximate analysis, then evaluates their main event devolatalization and combustion kinetics that used in high fidelity reactive flow modeling. In parallel low fidelity systematic analysis is carried out as a benchmark to the best conversion metrics. Should you like analytical analysis such as TGA, ICP, GC/MS and the combustion of solid waste using Drop Tube Reactor and you enjoy multi-physics flow simulation using Fluent this is a nice project to learn and advance your knowledge.

Desalination via membrane distillation known as Direct Contact Membrane Distillation. This project involves experimental setup and analyses and high fidelity CFD simulation of conjugated flow. You will have a chance to build your desalination unit using acrylic blocks and using (in-house electro-spun or commercial) super-hydrophilic thin membranes that separate two open flow chambers, one represents a fresh and another represents the brine. In this research numerous parameters as the role of membrane porously, thickness, conductivity, flow conditions (Re, temperature, turbulence intensity) have been investigated. You can push this research forward by start looking at what is happening to the brine diffusion adjacent to the membrane to improve the process efficiency in increasing the temperature and reducing the concentration polarization beyond what has been reported.

Freeze desalination which is a new trend in desalination due to the very low energy of fusion which is only 1/7th of the latent heat which consumed during thermal processes. You can use your 1st principle of cooling to estimate the time and energy utilization in the brine freezing process. Most importantly you will notice brine diffusion/migration occurs during freezing pushing the highly concentrated bine forward and leaving the lower salinity frozen crystal behind. You can guess that successive freezing and melting is the way forward. The project involve experimental setup at the macro and micro level: Using freeze dryer apparatus per the setup below and simple and micro-level using thermos electric Peltier setup. The goal is to gain more fundamental of the freezing as quenching will lead to homogenized freezing and trapping the salts while controlled directional freezing enables one to manipulate the diffusion of the brine leading to a lower salinity crystallization and hence taking advantage of low heat of fusion for energy saving. Your role is to design the perfect crystallizer, carry out two phase flow simulation that involves solid phase transition following the phase transition of the brine, and finally you may able to carry and design the entire process systematically emphasizing its feasibility.

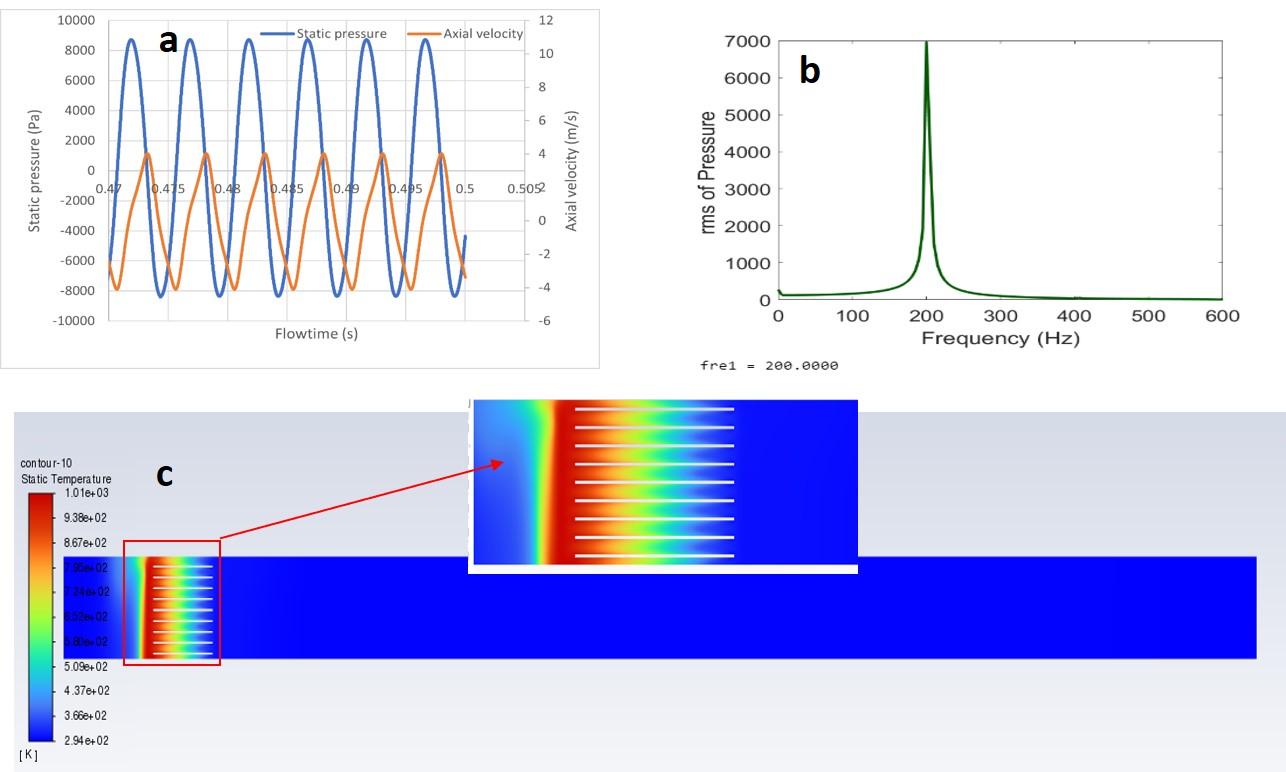

Thermo-acoustic is another active project that demonstrates the conversion of the waste thermal energy or concentrated solar energy into acoustic energy using and developing an acoustic engine, then use this source of acoustic energy as a prime mover to drive a heat pomp. A few papers have been published focusing on the role of the fluid medium, thermal energy intensity, and the geometry of the resonator. There are plenty of work to design the generator and the development of high fidelity conjugated heat transfer and optimizing the viscous penetration and thermal dissipation lengths. The project involved Design, Build and Test at every level and as system integration at high Carnot efficiency.

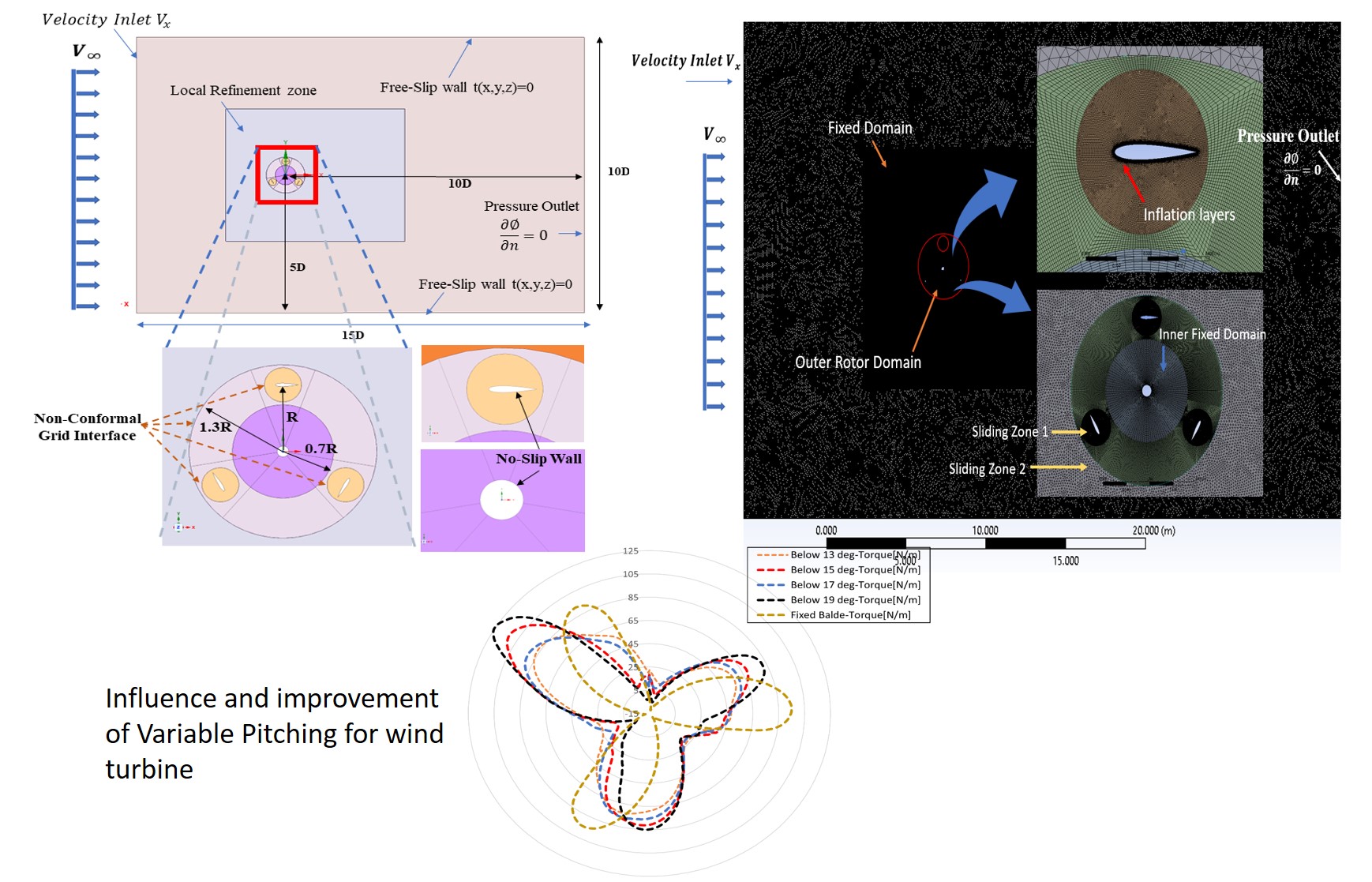

Flow over breathing/slotted/perforating bodies and variable pitching aero foil and wind energy. Over one set of geometries one is keen in reducing the drag, and in another the goal is to increase the lift. It all falls towards manipulating the boundary layer. The turbosail, optimizing suction & blowing over bluff bodies, flow over rotating bodies (single rotating cylinder, rotating turbine rotors, or flow over variable pitching turbine blades all belongs to this category.

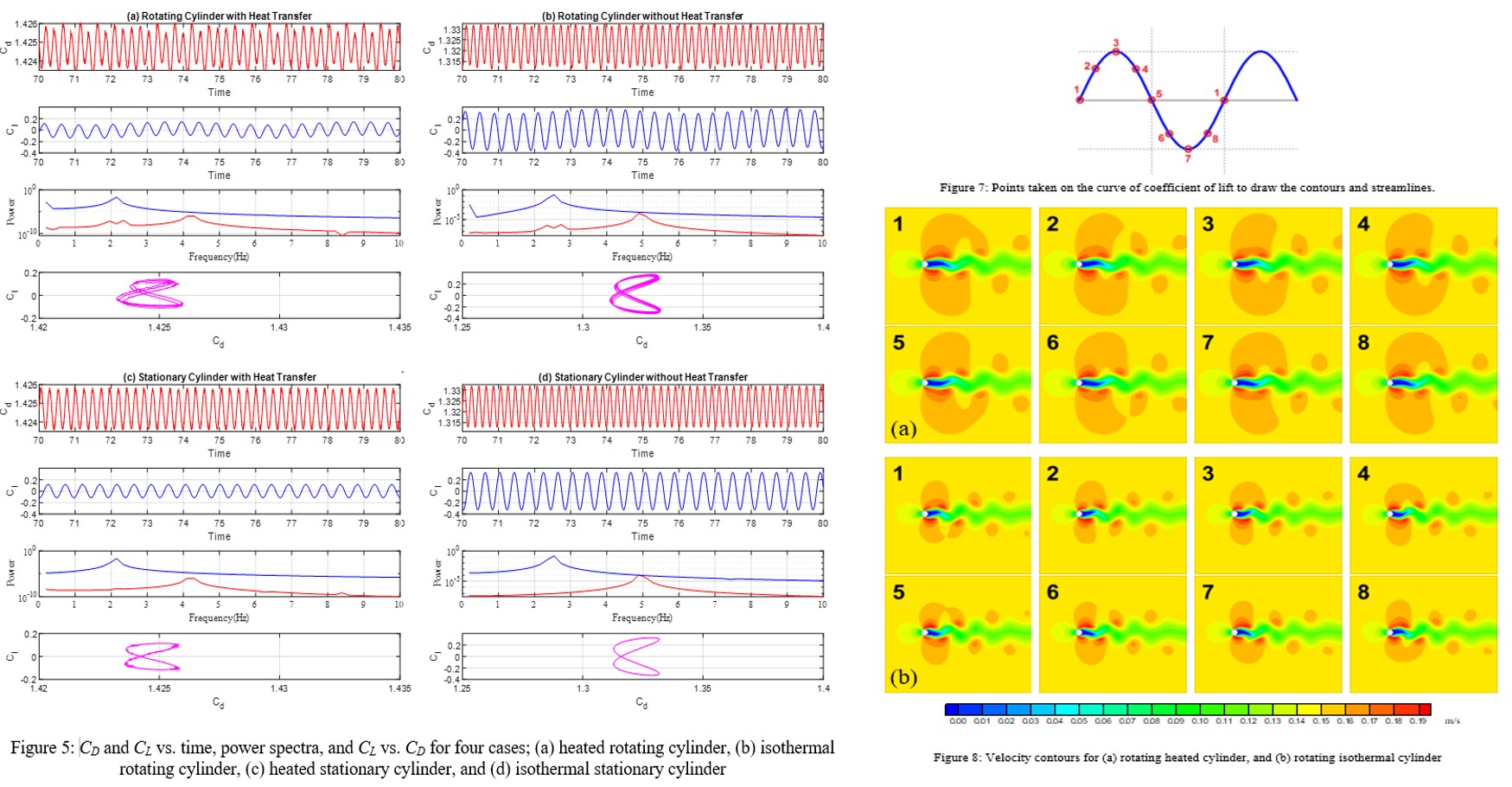

Flow Induced Vibration and fluid solid interaction: This is a funded CIRA 2020 project which enabled us to investigate the flow induced vibration on tube bundle heat exchangers. This conducted both experimentally and using multiple high fidelity CFD modeling covering single and tandem oscillating cylinders across the flow. Flow modal decomposition and passive and active flow control as well as oscillatory flow energy harvesting.

Abstract/Summary

Freeze desalination (FD) technology represents a transformative solution to the pressing global water crisis[1-3]. Traditional desalination methods often involve high energy consumption and environmental concerns. In contrast, FD exploits phase change and crystallization to efficiently extract freshwater from saline sources, offering a sustainable alternative with significant energy reduction. However, despite its promise, FD faces challenges related to system design and cold energy utilization additional to ion diffusion and entrapment that impede its full potential. Eutectic freeze crystallization (EFC) is a multicomponent solution for the rejected desalinated, and geothermal, brine which associated with negative environmental/marine life impact. The aim of EFC is to separate saline water into re-usable products: pure water as ice and pure salts that precipitate at their eutectic crystallization points, using relatively little energy compared to evaporative methods. We intend to performed technical and economical evaluation of the potential of EFC in treating brines using EFC lab experiments on synthetic brines and hydrogeochemical modelling (using USGS PHREEQC model or equivalent) of known geothermal brines. Overall, freeze concentration can result in significant reduction of the waste stream and the potential to produce usable water while using eutectic salt precipitation, i.e. hydrohalite (NaCl·2H2O), MgCl2.12H2O, Antarcticite, Sylvite, etc., with economic value[4-6]. The study of brine crystallization processes holds immense importance in the context of FD technology, offering solutions for water purification in various applications. This interdisciplinary research project aims at exploring and understanding brine nucleation and crystallization to enhance FD processes, ultimately contributing to sustainable freshwater production.

Problem Statement, Challenges and Potential Benefits:

This project endeavors to setup ice crystallization experimentation via a comprehensive approach, involving measurements, modeling & simulations techniques. with objectives:

(i) To characterize kinetics of ice crystallization: Considering factors such as temperature, solution composition, and surface properties. This will be done following EFC experiments setup showing reactor vessel(1), & stirrer(2) bottom or jacketed cooling of the vessel, sampling pump(3), collection vessel with solid/liquid filter(4)

(ii) To understand the growth and structural evolution of ice crystals macroscopically: By integrating experimental observations with simulation data.

(iii) To Enhance crystallization freezing: The knowledge gained from this project will facilitate the development of improved freeze desalination techniques, leading to more efficient and sustainable freshwater production. Our expert team possesses the necessary expertise, equipment, and materials to achieve these research objectives. We anticipate that the outcomes of this study will yield several high-impact research publications and provide an excellent learning opportunity for a Ph.D. student.

Desirable Outcomes and Deliverables

This research project envisions several key outcomes and deliverables. Firstly, develop in depth understanding of brine crystallization processes through a combination of experimental measurement and numerical modeling. Secondly, producing a substantial body of knowledge, which will contribute to the near zero brine reject and use of freeze desalination techniques.This project offers an exceptional opportunity to gain expertise in a multidisciplinary research environment, developing skills in CFD modeling, experimental techniques, and data analysis. The ultimate goal is to foster innovation in freeze desalination technology and address the pressing global need for sustainable freshwater resources.

Requirements:

My group is seeking a candidate with minimum MS in Mechanical Engineering or relevant program with a strong foundation in mathematics. Hand on Matlab or Python programming is desirable. An interest in two-phase flow and a willingness to delve deeper into non-isothermal multiphase CFD will be advantageous for this exciting and multidisciplinary research project. The work will involve numerical simulations, programming, and statistical data analysis as well as experimental development working in a team environment.

Key References/Bibliography

[1] El Kadi, K., & Janajreh, I. (2017). Desalination by freeze crystallization: an overview. Int. J. Therm. Environ. Eng, 15(2), 103-110.

[2] Janajreh, I., Zhang, H., El Kadi, K., & Ghaffour, N. (2022). Freeze desalination: current research development and future prospects. Water Research, 119389.

[3] Zhang, H., Savvopoulos, S., Hatzikirou, H., & Janajreh, I. (2023). Experimental and mathematically validated studies of pure water droplet freezing under natural free convection. Desalination, 555, 116512.

[4] Niels Hartog, Annet Baken, Nienke Koeman-Stein, Eutectic Freeze Crystallization (Efc): A Cool Solution For Processing Geothermal Waste Brines, European Geothermal Congress, Den Haag, The Netherlands, 11-14 June 2019

[5] Kalista, B., Shin, H., Cho, J., Jang, A., 2018. Current development and future prospect review of freeze desalination. Desalination 447, 167–181.

[6] De Graaff, B. 2012. “Eutectic Freeze Crystallization An Experimental Study into the Application of the EFC Process on Two Different Aqueous Waste Streams .” TU Delft.

[7] Lewis, A.E., J. Nathoo, K. Thomsen, H.J. Kramer, G.J. Witkamp, S.T. Reddy, and D.G. Randall. 2010. “Design of a Eutectic Freeze Crystallization Process for Multicomponent Waste Water Stream.” Chemical Engineering Research and Design 88: 1290–96. doi:10.1016/j.cherd.2010.01.023.

[8] Toner, J D, and D C Catling. 2017. “A Low-Temperature Aqueous Thermodynamic Model for the Na−K−Ca−Mg−Cl−SO 4 System Incorporating NewExperimental Heat Capacities in Na 2 SO 4 , K 2 SO 4 , and MgSO 4 Solutions.” Journal of Chemical & Engineering Data 62: 3151–68. doi:10.1021/acs.jced.7b00265.