A titanium implant with a structure mimicking bone may have better compressive behavior than traditional titanium implants, according to new research from Khalifa University.

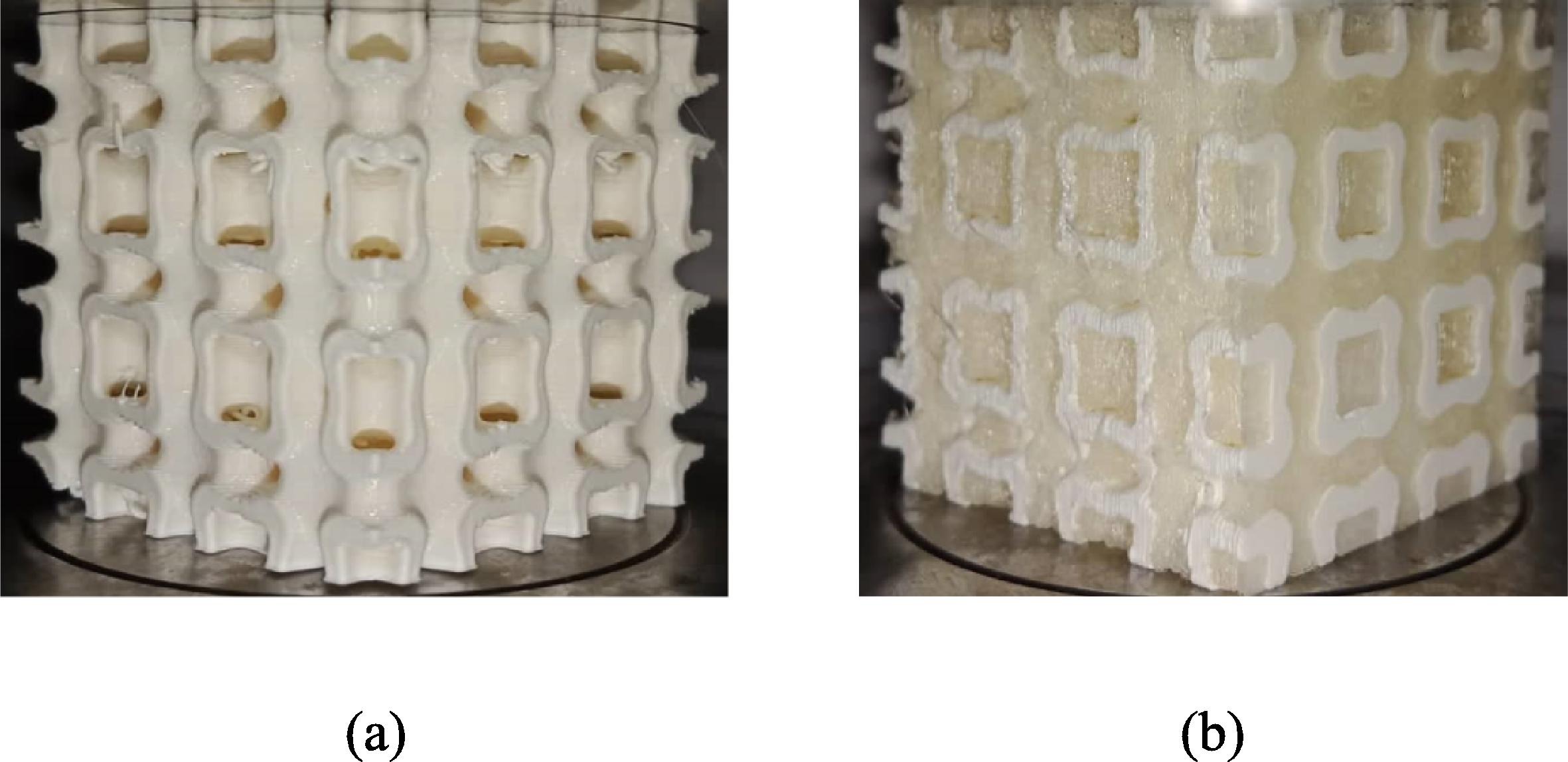

Researchers at Khalifa University developed a titanium orthopedic implant with a triply periodic minimal surface (TPMS) architecture. TPMS titanium implants offer several advantages over traditional implants due to their unique geometric structure and ability to be customized.

Dr. Nguyen Van Viet, Dr. Waqas Waheed, both Postdoctoral Fellows, Dr. Anas Alazzam, Associate Professor of Mechanical Engineering, and Prof. Wael Zaki, Professor of Mechanical Engineering, published their work in Composite Structures.

The TPMS structure is a type of geometric structure that has a repeating pattern of curved surfaces that minimize surface area while maintaining structural integrity. This structure can provide several advantages for orthopedic implants, such as improved strength, stiffness, and wear resistance. Additionally, functionally graded TPMS titanium implants can offer varying material properties depending on the design: An implant could be designed with a stiffer region for load-bearing purposes and a more flexible region for improved tissue-implant interaction.

Bone comprises an open-cell composite material, but its mechanical properties vary with anatomical location and the loading direction. Therefore, a material that can be changed to suit differing requirements is highly desired.

Understanding the compressive behavior of functionally graded TPMS titanium implants with ingrown cortical or trabecular bone is critical for developing effective implants. If misunderstood, implants could lead to failure, causing further complications for the patient. Additionally, the different types of bone may interact differently: The type of bone tissue that grows into the implant can vary depending on the location of the implant and the surgical procedure used. For example, in some cases, the implant may be surrounded by cortical bone, which is dense and compact bone tissue, while in other cases, the implant may be surrounded by trabecular bone, which is less dense and more porous.

Trabecular bone is found at the ends of long bones and in other locations where bones meet to form joints. It is less dense and more flexible than cortical bone, which is the denser outer layer of bone tissue. The lattice structure of trabecular bone provides a large surface area for the attachment of bone cells and blood vessels and also allows for the transfer of mechanical loads across the bone tissue.

Implants with ingrown trabecular bone may then have better compressive behavior than those with ingrown cortical bone due to differences in the mechanical properties of the two types of bone tissue. Therefore, understanding the behavior of these implants could lead to the development of more effective and efficient orthopedic implants, which can improve patient outcomes.

“Functionally graded porous materials are interesting for bone-implant applications because they allow tailoring of the effective mechanical properties by allowing structural gradations in composition, porosity, and feature size,” Prof. Zaki said. “These gradations may be engineered to maximize internal surface area to facilitate cell attachment, while also optimizing fluid flow for better distribution of nutrients and designing the material architecture to closely match the stiffness of bone. A mismatch in stiffness between implant and bone is a major concern because of the resulting stress-shielding effect at the implantation site, which may cause bone resorption and require revision of the surgery.”

To investigate the compressive behavior of the TPMS titanium implants, the researchers used finite element analysis, a computational technique used to simulate the behavior of complex systems under various conditions. The researchers modeled the implants with different degrees of bone ingrowth and evaluated the stress and strain distributions.

They found that the implants with ingrown cortical or trabecular bone exhibited superior mechanical performance compared with the homogenous titanium implant, although the effective compressive modulus of the implant with ingrown trabecular bone was higher than with cortical bone. This is due to the more porous structure of the trabecular bone, which is better suited to transferring compressive loads. Additionally, the TPMS titanium implant’s effective compressive modulus increased with increasing degrees of bone growth, indicating that the implant’s mechanical properties became more similar to those of the surrounding bone as bone ingrowth increased.

“The experimental evidences showed that the bone cell can partially fill the cavities of porous implants, which then affects the mechanical behavior of the implant,” Prof. Zaki said. “Separate networks of interconnected cavities within the implant may be engineered to provide an effective stiffness that closely matches that of bone, while at the same time facilitating osseointegration.”

The researchers also found that the TPMS titanium implant with ingrown bone had a more uniform stress distribution compared with the homogenous titanium implant, suggesting that the implant with ingrown bone is less likely to develop stress concentrations, which can lead to implant failure.

Research within the scope of this project will pave the way for the development of architected repair and replacement solutions for biological tissues that may not be limited to bone. The team is also considering alternatives to titanium for the development of high-performance lattice and composite biomaterials.

Jade Sterling

Science Writer

25 April 2023