Research into cutting-edge hydrogel electrolytes for zinc metal anodes offers a promising future for wearable devices

In the 15 years since the first health wearables were first released, their realm has rapidly expanded. Roughly one in four adults now uses some kind of fitness tracking device. The market is growing, but these devices are limited by their power supplies: Wearables contain sensors that need plenty of battery power, and batteries can only be so big before the devices are too cumbersome to be appealing to consumers. The demand for flexible and reliable power sources is on the rise, and a team of researchers including Khalifa University’s Prof. Jang Kyo Kim, Department of Mechanical Engineering, has investigated hydrogel electrolytes for flexible zinc-ion batteries to meet this demand.

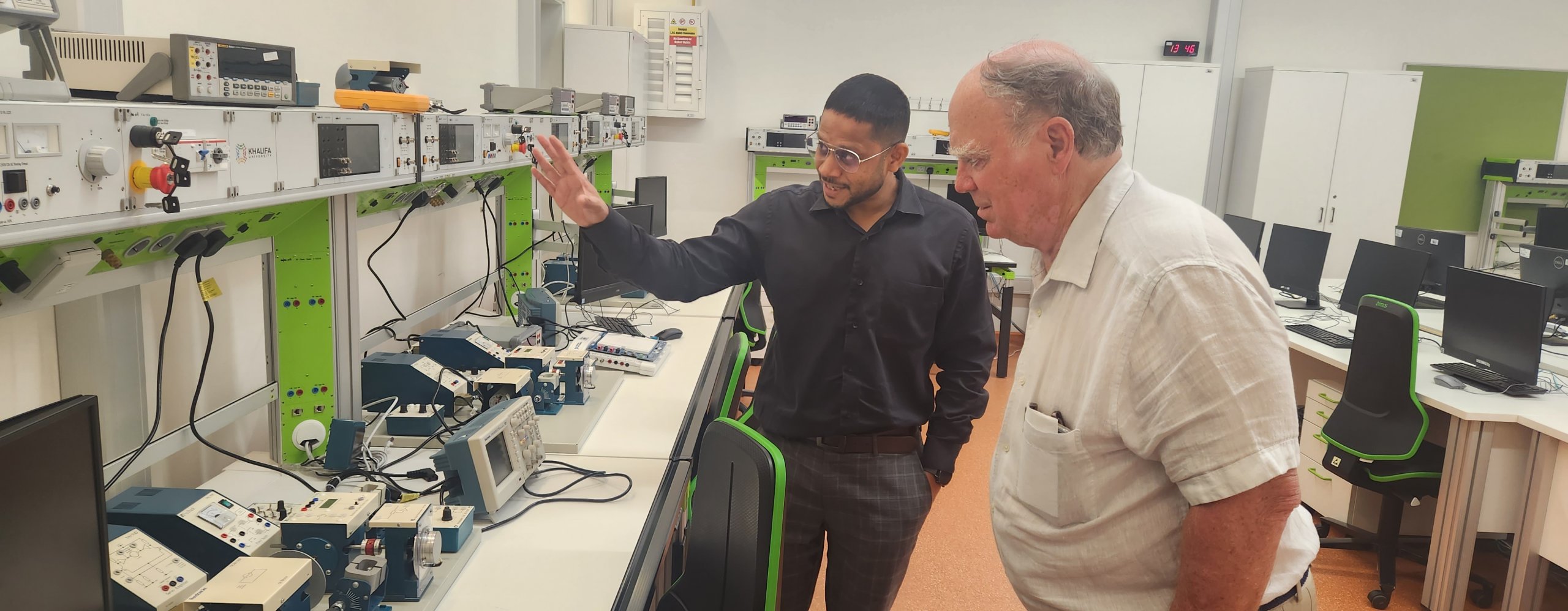

Prof. Kim collaborated with researchers from the Hong Kong Polytechnic University and Tsinghua University, China, to analyze how the hydrogel bends and compresses with stress. To integrate seamlessly with wearable electronics, these materials must exhibit exceptional mechanical stability. They must endure not just the initial stress of assembly but also the long-term strains of repeated charging and discharging reactions and withstand significant deformation as the devices move with the human body.

“While extensive studies have been conducted on optimizing the chemical structure and boosting tensile elasticity, the mechanical stability of the hydrogel under repeated deformation is largely overlooked, leading to unsatisfactory performance at large cycling capacity,” Prof. Kim said. “We systematically analyzed the compressive fatigue-resistance properties of the hydrogel electrolyte, revealing the critical roles of the salt and copolymer matrix on how cracks start and develop. This is the first study of its kind to show how hydrogel electrolytes can be engineered to make advanced zinc-ion batteries that can be used in flexible devices.”

The team published their results in Advanced Materials, a top 1% journal for mechanical engineering and materials technology.

Battery systems for wearable electronics must not only bend and stretch with the body’s movement but also comply with stringent safety standards. Rechargeable aqueous zinc metal batteries offer affordability and safety in next-generation battery systems but aqueous electrolyte solutions aren’t practical for wearables. Replacing the aqueous electrolyte with a hydrogel could be the solution, as the researchers found.

These hydrogels work by immobilizing free water molecules to reduce their reactivity and curb the issues commonly seen in aqueous electrolytes that compromise the battery’s lifespan. The ideal hydrogel electrolyte also needs to withstand repeated deformation and use. The research team used polyacrylamide-based hydrogels, known for their elasticity, and found the optimal hydrogel using zinc, polyacrylamide and chitosan (C-PAMCS) demonstrated remarkable anti-fatigue properties under repeated compression, with a cyclic lifespan of over 1,500 hours at high current rates and capacities.

“Through systematic studies of zinc anodes employing various hydrogel electrolytes, we showed that the anti-fatigue property plays a vital role in guaranteeing the stability and integrity of the hydrogel. Interestingly, their fatigue damage behavior follows the well-known Miner’s rule which was developed to explain fatigue failure of solid materials like metals,” Prof. Kim said. “Both the salt and polymer matrix significantly affect the mechanical stability of the hydrogel under cyclic compression, and our engineered C-PAMCS stands out as an ideal choice for high-energy zinc anodes. The battery exhibits remarkable flexibility and stability that would be attractive for powering wearable electronics.”

Jade Sterling

Science Writer

29 November 2023