- Admissions

- Academics

- Research Office

- Student Life

- News & Events

- Outreach

- About

Aerospace Structures

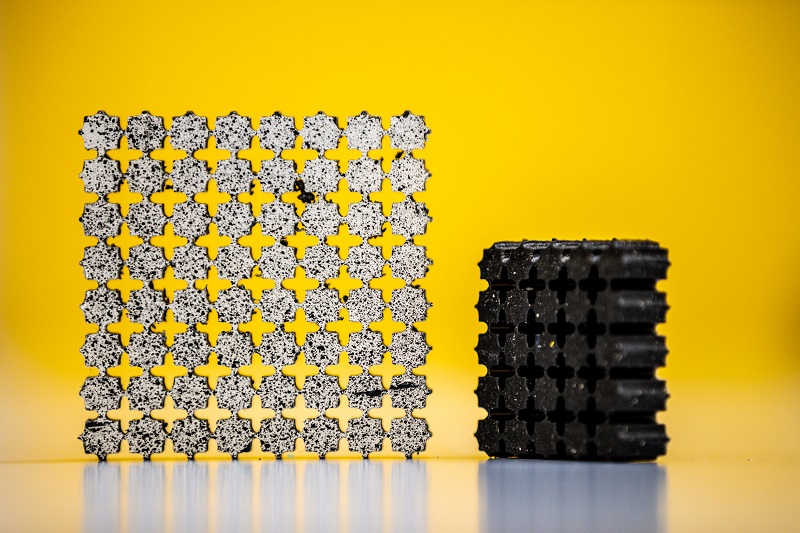

Given that the empty weight of an aircraft is approximately 50% that of its maximum take-off weight, there are growing demands to reduce the mass of critical structural components, such as the fuselage, wings and tailplane. Current research on aerospace structures at KU is investigating new lightweight designs that can out-perform existing components. Here, new types of sandwich structure with novel cores are being developed that offer similar properties to existing structures, but are much lighter. Examples include all-composite sandwich structures in which both the skins and the core are manufactured from high-performance composites, such as carbon fiber reinforced plastics. These are some of the lightest designs that currently exist and they are likely to lead to significant changes in the performance of the next generation of both civil and military aircraft. Attempts are also being made to model the behavior of these structures and to predict their operational lifespan.

Computational Mechanics of Composite Materials

With the advent of novel materials such as responsive fibers, active particles, graphene and carbon nanotubes, composites and architected cellular materials can now be made multifunctional by incorporating mechanical, thermal, electrical, magnetic, optical and/or other functionality by varying constituents and microstructural arrangements. The use of these advanced multifunctional composites has been drastically increased in engineering applications such as aerospace, automotive, biomedical, energy and oil and gas industries. During their life time these composites are often exposed to simultaneous mechanical, thermal, electrical, magnetic and non-mechanical effects, such as diffusion of fluid, extreme environments, chemical reactions that affect the mechanical properties of the composites and leading to strong coupling between various physical properties in the composites. Researchers at KU are developing experimentally validated macro/micro/nano-mechanics-based constitutive theories for small and large deformation multi-scale and multi-physics behavior of polymers and metals. Emphasis is on developing various theoretical and computational micromechanical models to predict the properties, performance and durability of advanced multifunctional materials, metamaterials, architected lightweight cellular materials and composite structural systems. The advantage of micromechanical models is that they are capable of predicting the effective behavior of composites subjected to concurrent mechanical and other stimuli while recognizing multi-field responses of the constituents. These outline some of the research areas that are being investigated at Khalifa University. If you are interested, please contact the relevant member of staff in order to get more information.