- Admissions

- Academics

- Research Office

- Student Life

- News & Events

- Outreach

- About

Aerospace Manufacturing

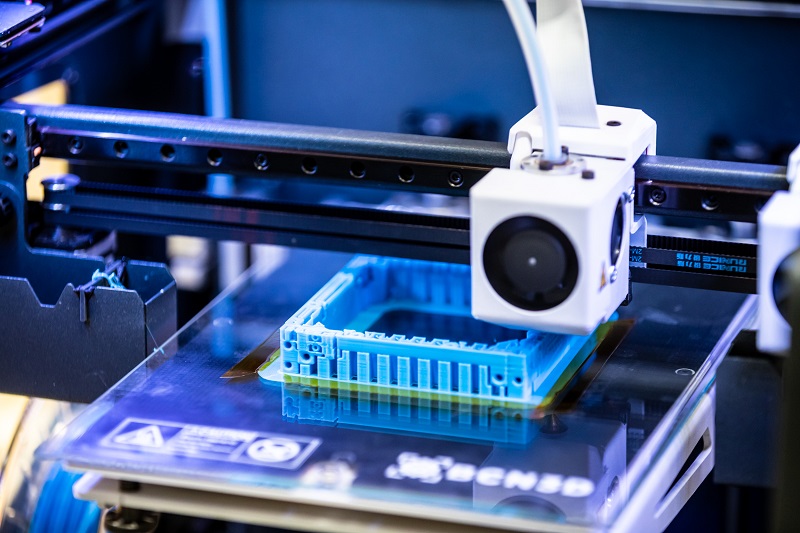

Composite materials are being used in ever greater amounts in the manufacture of aircraft structures. For example, the Boeing 787 is largely produced from carbon fiber reinforced plastic. Faced with the challenge of manufacturing large composite components at low cost, engineers are looking for new and novel ways to produce them. Researchers at KU are investigating new routes for manufacturing lightweight structures, such as resin infusion, out of autoclave processing, automated fiber placement and additive manufacturing (3D printing). These techniques enable components to be manufactured very quickly and precisely, keeping costs down whilst driving performance up. There remain many hurdles that have to be overcome, such as understanding how the processing parameters affect the properties of the finished component. Work is also underway to predict how the materials within the composite will behave during the processing cycle. Here, finite element techniques are being used to enable engineers to design the next generation of Composite structures with greater confidence.

Aerospace Nanomaterials & Nanocomposites

Recent exciting developments in the area of nanotechnology will soon offer engineers the possibility of building ultrahigh performance aircraft starting at the atomic scale. The resulting structures will be incredibly strong and very light (for example graphene is more than one hundred times stronger than steel). Researchers at Khalifa University are introducing carbon nanotubes, carbon nanofibers, graphene and other two-dimensional heterogeneous materials into conventional composite materials in order to improve their toughness and to make them damage-tolerant and more resistant to impact and fatigue loading. Techniques are also being developed to ensure that the carbon nanomaterials are evenly dispersed throughout the composite, avoiding the occurrence of unwanted aggregations or grouping of these nanometer-sized materials. Future research will consider effective ways to manufacture nanocomposites and also investigate ways to fully benefit from the enormous potential offered by these amazing materials.

Architected Multifunctional Materials and Composites

Design of new materials and composites that are durable, lightweight, and multifunctional are commonly inspired by natural materials and composites. However, as engineers we are no longer limited to the natural patterns as we can design our own architected materials and composites (i.e., meta-materials and meta-composites). These will transform the way materials and composites are designed to achieve several engineered properties, and shift the material creation paradigm from structure→processing→property to property→architecture→fabrication. Researchers at Khalifa University are engaged in the development of novel types of lightweight, damage-tolerant, and multifunctional materials and composites that are architected to enhance the performance of aerospace structures and other engineering systems. Additive manufacturing (3D printing), which is at the forefront of fourth industrial revolution, is used for fabricating these new materials and composites. Furthermore, complex theoretical and computational modeling is used to guide the design of such materials and composites.