Nanografen (Turkiye)

Assoc. Prof. Dr. Burcu Saner Okan received BS degree in Chemistry at Middle East Technical University (METU), Turkey in 2005. Dr. Saner Okan received MS degree in 2007 and PhD degree in 2011 in Materials Science and Engineering programme at Sabanci University. Dr. Saner Okan is an academic director of Sabancı University Composite Research Center since March 2022, and also a research and application-oriented faculty member at Materials Science and Nanoenginnering and Manufacturing technologies at Sabanci University since 2017. In addition, Dr. Saner Okan is co-founder of NANOGRAFEN Nano Technological Products Company. Dr. Saner Okan develops cost-effective and lightweight composites parts reinforced by waste tire-derived Graphene NanoPlatelet with part producers and leading OEM partners. Nanografen is in the supplier list of Renault Global to use as a reinforcement in thermoplastics. Dr. Saner Okan has an expertise in graphene, polymer nanocomposites, compounding, surface chemistry and electrospinning, recycling and upcycling, circular economy. She has more than 40 articles published in international journals, 7 book chapters, 2 patents and more than 50 conference papers in these fields.

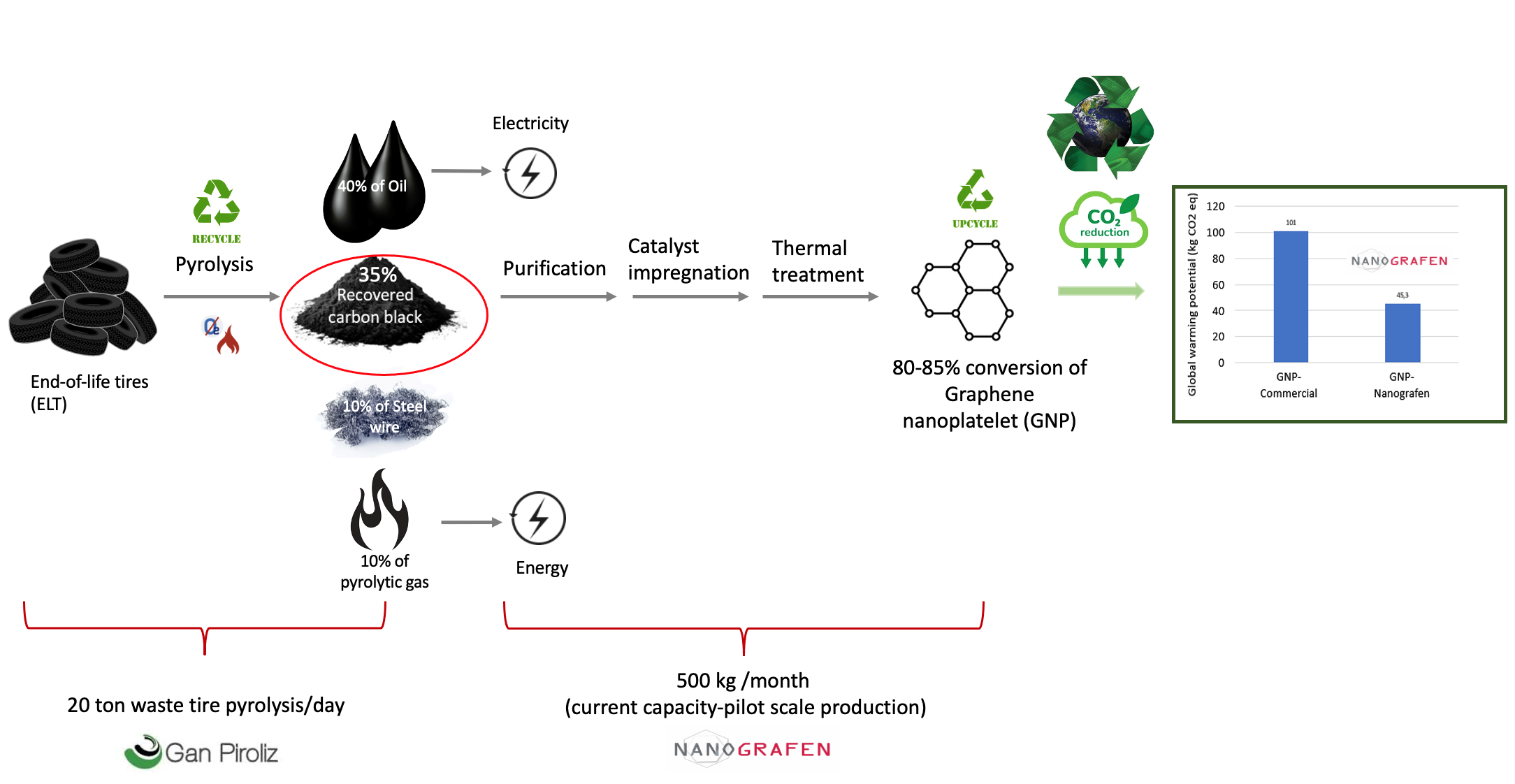

Upcycling is a significant concept to bring an end to the life cycle of materials and open various new application routes for nanomaterial production from waste sources. The present work provides an insight into the importance of green synthesis methods in graphene nanomaterials synthesis by combining recycling and upcycling technologies. We developed a scalable technology to produce graphene nanoplatelets (GNP) from recovered carbon black obtained from the pyrolysis of end-of-life tires by using recycling and upcycling technology. With this developed technology, a pilot production line with the capacity of 500 kg/month in Nanografen Co (start-up company of Sabancı University) was established to initiate the industrialization of graphene in thermoplastic sector. Nanografen becomes an official supplier of Renault together with Ravago and they developed OEM certified masterbatch to reduce glass fiber and mineral amount in polypropylene and polyamide based interior and exterior parts. Consequently, this multidisciplinary work ensures significant innovation potential of graphene in the field of thermoplastic-based composites and initiates the mass production by lowering cost from raw material to the selected part and overcomes the needs by addressing greenhouse gas emissions with sustainable designs by integrated manufacturing technologies of injection, overmoulding, and joining techniques. To conclude, Nanografen’s novel and sustainable solution supporting by appliying eco-efficient manufacturing technologies and using Life Cycle Assessment provides CO2 emission reduction of at least 10% in each application by adopting eco-design and a circular economy approach.

Figure 1: Nanografen’s technology

Figure 1: Nanografen’s technology