Improvement on RFCC Catalyst towards High Stability and Activity (2.5 million aed), PI: Assist. Prof. Maryam Khaleel

Even though fluid catalytic cracking (FCC) process started ~75 years ago, it is still the prominent conversion technology in the oil refinery to produce gasoline, propylene and other valuable products. In spite of efforts to find alternative energy resources to meet sustainability and environmental protection, the difficulties on massive production of renewable energy suggest continuing use of oil for many decades due to its maturity, efficiency and the availability of technology know-how. Undoubtedly, zeolites are vital catalysts and the major component in the FCC process to date. ~ 2,300 metric tons of FCC catalysts are produced per day, which means that ~0.16 kg of FCC catalysts are required for converting one barrel of feedstock.

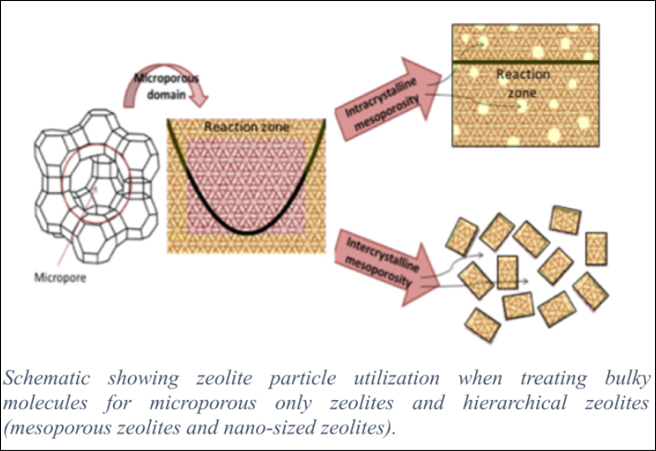

However, the amount of utilization of zeolite catalysts depends on the feedstock. For instance, resid feedstock needs more catalyst than lighter feeds. Irrespective of the feed properties in FCC, occurrence of catalytic activity loss necessitates addition of certain percentage of fresh catalysts to the catalytic reactor on a daily basis in order to maintain the desired conversion. Therefore, increasing the stability of the zeolite phase can enhance the economics of the process. The recent addition of RFCC (residue FCC) in order to process heavy feed in refinery operations worldwide motivated researchers in both academia and industry to further explore ways to improve catalyst stability, activity and selectivity. We propose strategies to improve catalysts for RFCC applications by synthesizing zeolite Y with tunable (hierarchical) porosity.