Electrical components made from paper and graphene oxide could mark the next breakthrough in flexible wearable electronics for a wide range of applications

Researchers from Khalifa University’s System-on-Chip Laboratory (SoCL) have developed a flexible memristor device using cellulose and graphene oxide that has the potential to revolutionize wearable electronics. It is low-cost, flexible, biocompatible and conveniently disposable. They published their original work in MRS Bulletin and a further study testing their material for ultraviolet and sunlight monitoring in Nanoscale Research Letters.

The team included Dr. Anas Alazzam, Associate Professor of Mechanical Engineering, Dr. Nahla Alamoodi, Assistant Professor of Chemical Engineering, Prof. Baker Mohammad, Director of the SoCL, Dr. Heba Abunahla, Research Scientist, Ahmed Abusultan and Ahmad Chaim, MSc students.

In principle, a memristor device is composed of a metal oxide sandwiched between two electrodes. It has the ability to change its resistance under the application of an applied voltage. As the name implies, the memristor can remember its last written state, even if the power is turned off, which offers great potential for use as a solid-state computer memory device.

Unlike traditional solid-state storage technologies, memristors require less energy to operate, last longer, and store at least twice as much data. They use architectures that allow them to perform in-memory computing, which solves a traditional computing problem of needing to move data from memory to the processing unit before performing computing functions.

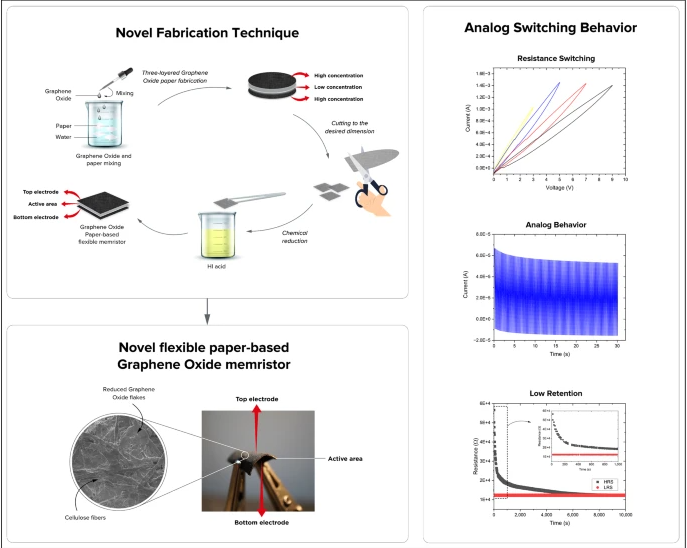

Now, the material and fabrication approach employed by the research team makes memristors metal-free and even more flexible. The material developed offers physical flexibility and is made of carbon and oxygen. The research team developed a three-layer paper memristor device, named PrMem, using a novel low-cost fabrication technique. All three layers — the top electrode, active layer, and bottom electrode — are made of the same materials, cellulose and reduced graphene oxide, but with different concentrations.

Because the device is made entirely of cellulose, the structural component of plants that is used to produce paper, it is hydrophilic, which means that liquids may flow freely through its porous structure. This simple capillary action eliminates the need for additional mechanical pumping structures, making PrMem a promising candidate for a variety of applications, Dr. Alazzam said.

Graphene is already widely used in a range of applications for its outstanding features. It is flexible, low-cost and adaptable for many applications. The flexibility allows the PrMem device to be integrated into electronics that are built on flexible surfaces for applications such as smart wearable devices, where flexible sensing is vital.

One such application is monitoring ultraviolet (UV) light and solar exposure.

“Sunlight, namely UV light, is the principle source of vitamin D for the human body,” Dr. Alazzam said. “However, overexposure has been linked to the development of various diseases. Continuous monitoring of UV exposure at the individual level is critical to ensuring that exposure is managed safely and effectively.”

Existing monitoring devices use photochromic and photoelectric sensors. Photoelectric sensors use a wide bandgap semiconductor integrated within an electric circuit that absorbs and measures UV radiation within a specific bandwidth. Photochromic sensors change color in response to UV emission without requiring any electrical input.

The SoCL research team, with Ahmed Abusultan, MSc student, and Dr. Yasmin Halawani, Postdoctoral Fellow, developed a sensor using their memristor material.

“The sensor is entirely composed of paper and is photosensitive due to the incorporation of graphene oxide in the structure of the paper,” Dr. Alamoodi said. “It can be worn on the body as a patch, and sunlight or UV exposure can be estimated by observing the color change in the patch after being exposed to sunlight. A UV monitoring sensor with an artificial intelligence application that is compatible with mobile devices is used to estimate sunlight exposure by analyzing color changes and correlating them to exposure energies. Graphene oxide has ‘exposure memory’ as a result of the reduction process, which means that changes in its chemical and physical properties are permanent. This memory aids in tracking UV or solar radiation exposure and enables offline measurements at any time after exposure is complete.”

Jade Sterling

Science Writer

15 November 2022