A team of researchers from Khalifa University has developed a breakthrough approach to water treatment as innovative low-cost, eco-friendly membrane could revolutionize toxic phenol removal from water.

Removing phenol from industrial water is a pressing global issue. A persistent organic pollutant, phenol is commonly used in agriculture and general disinfection. Long-term exposure to phenol can damage human health and potentially cause cancer, but despite the risks, phenol is an indispensable chemical in various manufacturing industries, making it hard to completely eliminate its use.

However, its poor biodegradability means it cannot be removed from wastewater by conventional methods. Traditional methods, like distillation and degradation, are either energy-intensive or lead to secondary pollution and increased costs. Removal by adsorption is more energy-friendly but can also result in secondary pollution due to the breakdown or leaching of adsorbents.

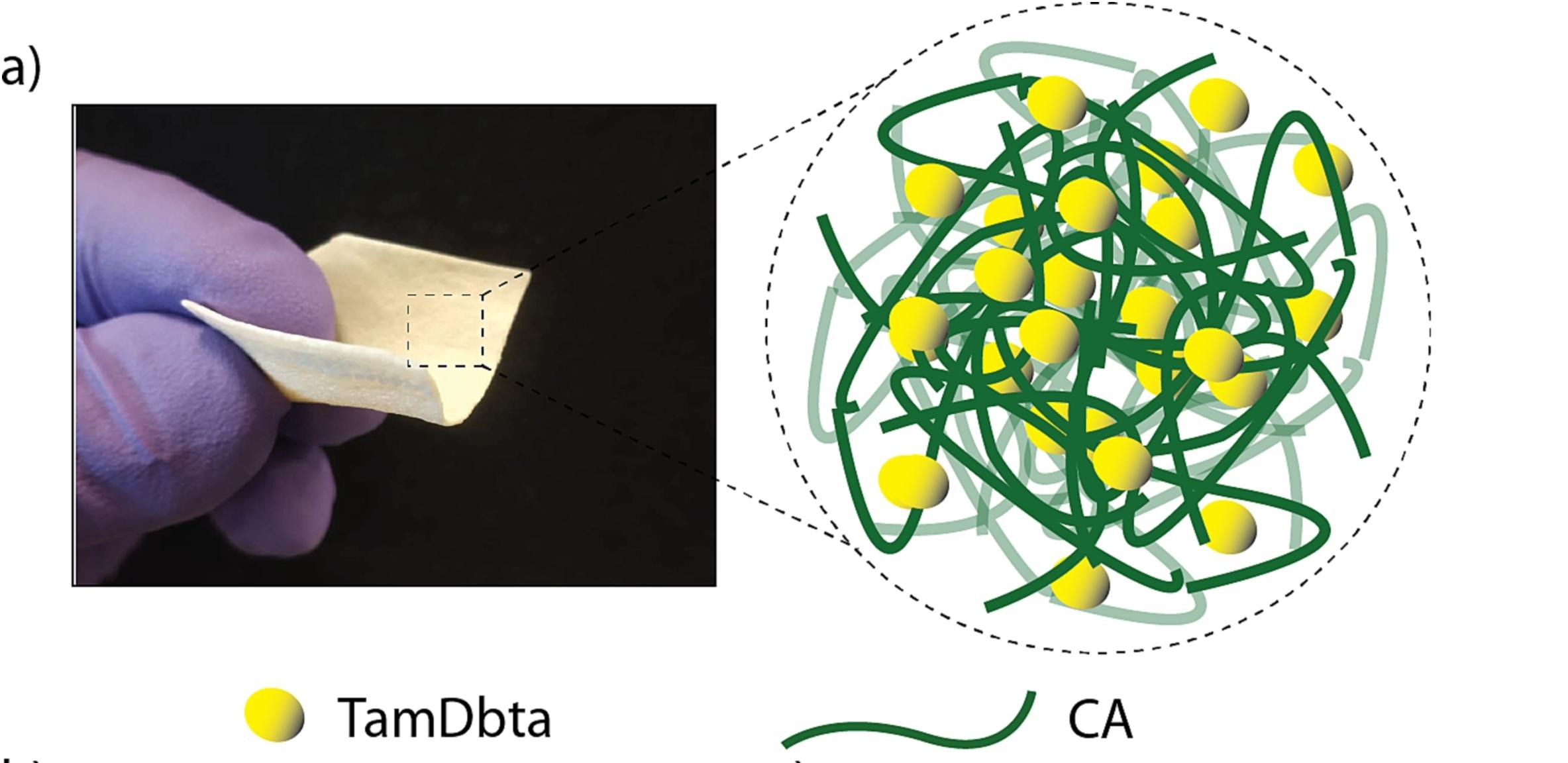

A team of researchers from Khalifa University’s Departments of Chemistry and Chemical Engineering, Center for Membranes and Advanced Water Technology, and Center for Catalysis and Separations has developed an effective phenol decontamination method using a 3D-pillars induced membrane of cellulose acetate (CA), a synthetic fiber made from tree pulp. Membrane-based separation is an energy-efficient method that avoids the risks of secondary pollution, but developing these membranes comes with its own set of challenges, including creating the correct porosity and functionality to filter phenol effectively.

Dr. Abdul Khayum Mohammed, Dr. Jisha Kuttiani Ali, both Postdoctoral fellows, Mahira Bashri Selman Kuzhimully, PhD student, Dr. Emad Alhseinat, Associate Professor, and Dr. Dinesh Shetty, Assistant Professor, with Dr. Matthew Addicoat, Nottingham Trent University, published their results in Chemical Engineering Journal, a top 1% journal in industrial manufacturing and engineering.

The team used cellulose acetate to address the issue of economic viability: CA is a naturally abundant, biodegradable, and inexpensive polymer. It can easily be fashioned into porous polymeric membranes, and its polar functional groups increase the hydrophilicity of the membrane, facilitating the smooth flow of water molecules. By adding nanopores and suitable functional groups, the team enhanced phenol removal.

The researchers developed a nano-porous 3D pillars-doped CA membrane. The mixed-matrix membrane uses a 3D covalent organic framework (COF), a structure capable of harboring functional molecule networks within its structure. The 3D COF framework creates open porosity with interconnected nanochannels, promoting smooth molecular diffusion. The team strategically controlled the growth of the COF at the nanoscale, which resulted in multiple functional sites and allowed for its even distribution within a mixed matrix membrane based on a common solvent used in membrane fabrication.

When tested on synthetic oil manufacturing wastewater, the results were promising: the research team’s membrane demonstrated an 80 percent removal rate for phenol. Even across a wide pH range and under high salinity conditions, the performance stability remained high, highlighting the potential of using carefully designed COFs as a key component in commercially viable polymer membranes.

“This innovative development signals a breakthrough for toxic phenol removal on an industrial scale,” Dr. Shetty said. “It serves as testament to the potential of leveraging eco-friendly, economic materials, and the power of science to address urgent environmental challenges.”

Jade Sterling

Science Writer

20 July 2023