From rain falling from clouds to dew forming on leaves, condensation is a natural and common occurrence. While most people wouldn’t give it another thought beyond putting a coaster under a glass of cold water, research into the mechanism of condensation formation and how this can be optimized for industrial purposes is gaining traction.

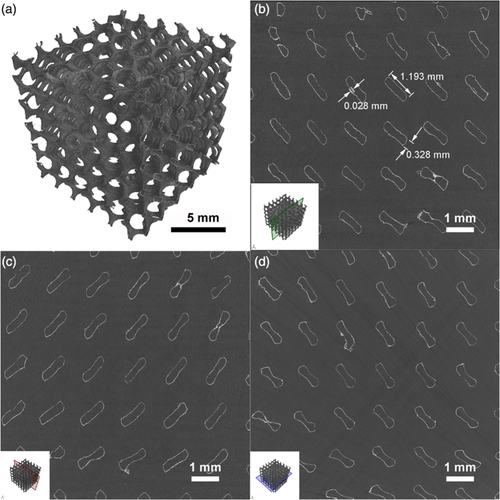

In a paper published in the Journal of American Chemical Society —ACS Applied Materials and Interfaces, the research team led by Dr. TieJun Zhang, Associate Professor of Mechanical and Materials Engineering, discovered a previously unobserved condensation phenomenon of satellite droplet formation on lubricant-cloaked water droplets using environmental scanning electron microscopy. This was a surprising result as one of the cloaking lubricants used were previously found to eliminate cloaking during water condensation.

The team comprising of Dr. Zhang, Qiaoyu Ge, Khalifa University PhD student and lead author of the paper, Postdoctoral Fellows Aikifa Raza and Hongxia Li, and Dr. Soumyadip Sett and Dr. Nenad Miljkovic from the Department of Mechanical Science and Engineering at University of Illinois at Urbana-Champaign (UIUC), investigated how infusing lubricants into condensation surfaces affects condensation performance, throwing considerable light on cloaked condensate droplet dynamics.

“Condensation is a phenomenon commonly found in many natural and industrial processes, including atmospheric dew formation, power generation, natural gas processing, water harvesting, and refrigeration,” explained Dr. Zhang. “Depending on the surface tension of the condensate and the surface energy of the surface, two distinct condensation mechanisms can occur: either dropwise or filmwise condensation.”

Condensation is a crucial component of distillation, an important laboratory and industrial chemistry application used to separate and purify liquids. In dropwise condensation, the condensed vapor forms droplets on a surface instead of a continuous film. The small droplets that form at the nucleation sites on the surface grow as a result of continued condensation, coalescing into large droplets. Once large enough, the drops fall.

Filmwise condensation, on the other hand, tends to wet the surface, forming a liquid film. As more vapor condenses, the thickness of the film increases in the flow direction as the liquid flows down the cooling surface under the action of gravity.

“Filmwise condensation is much easier to achieve for a variety of working fluids due to the relatively high surface energy of solid surfaces,” explained Ge. “However, dropwise condensation is preferable for more applications owing to its higher heat transfer performance.”

Heat transfer in dropwise condensation is up to ten times greater than in filmwise condensation, as a large area of solid surface is directly exposed to the vapor for dropwise. In many chemical and industrial applications, dropwise condensation is preferred and chemicals are used to ensure that dropwise condensation takes place.

Extensive studies have been conducted to encourage or ‘promote’ dropwise condensation by surface modification, including hydrophobic (water repelling) coatings and micro- or nano-texturing.

For liquids with low surface tension, such as natural gas and refrigerants, hydrophobic coatings (which are water repelling) and texturing are not effective due to the nonpolar nature of both the coating and the fluid, resulting in film formation. To enable dropwise condensation of these low surface tension fluids, researchers have been investigating lubricant-infused surfaces (LISs) to take advantage of the low surface tension of the infusing lubricant.

“Although the low surface tension of the lubricant helps to achieve dropwise condensation, it also causes problems of cloaking at the condensate-vapor interface,” explained Dr. Miljkovic at UIUC. “The lubricant can spread on the condensate droplet, thereby encapsulating it and forming a thin cloaking layer, which adds heat and mass transfer resistance and hinders growth of the droplet.”

LISs reduce the overall thermal resistance during condensation when compared to superhydrophobic surfaces without the lubricant. Rapid droplet shedding, as droplets become large enough to fall, allows fresh nucleation sites to be continuously replenished, thereby enhancing the rate of condensation and heat transfer performance.

“We conducted experiments of water vapor condensation on nanotextured superhydrophobic copper surfaces, which were infused with different types of lubricants,” said Ge. “We demonstrated that some of these lubricants, although used as non-cloaking lubricants in prior literature, in fact cloak water droplets.”

Cloaking of condensate droplets leads to additional thermal resistance, inhibiting droplet growth as the vapor comes into contact with the lubricant layer instead of the liquid condensate. However, despite the reduction in heat transfer performance, the formation of satellite droplets provides larger surface area for the vapor to condense.

“Our work, for the first time, described formation of satellite droplets, characterized their morphologies and analyzed different roles of the cloaking film with different tools,” explained Ge.

“The presence of satellite droplets on the cloaked lubricant layer indicates additional nucleation sites for vapor to condense. This provides an opportunity for enhancing the condensation rate and can in turn lead to significant heat transfer gains. At the macroscopic scale, the presence of the cloaking film played an important role in mobilizing water droplets without any external forces.”

“Despite the observations in environmental scanning electron microscopy, we also confirmed presence of the nano-scale cloaking lubricant film on the water droplets with a novel characterization approach based on Raman spectroscopy,” explained Dr. Raza. “The cloaking lubricant acts as an additional surface for vapor to condense, leading to the formation of satellite droplets. Again, this increases the overall surface area, meaning more condensation.

“We have made significant research progress and multiple joint publications with the UIUC team are on the way. It’s exciting when experimental data and in-depth analysis sheds light on previous findings. Without the great research infrastructure at Khalifa University, we wouldn’t be able to make this happen.”

“This is a remarkable achievement,” said Dr. Dalal Najib and Daniel Placht from the US National Academy of Sciences, one of the research supporters. “It is rewarding to see Dr. Zhang and Dr. Miljkovic leverage the Arab-American Frontiers program to establish joint research activities between their respective groups and produce tangible research results. The ultimate goal of the Frontiers program is to foster this type of high quality research collaboration between US and Arab institutions.”

Jade Sterling

News and Features Writer

11 May 2020