A new type of 3D-printed feed spacer could make membrane-based seawater desalination processes, such as reverse osmosis and ultrafiltration, more efficient, according to new findings by researchers at Khalifa University’s Center for Membranes and Advanced Water Technology (CMAT).

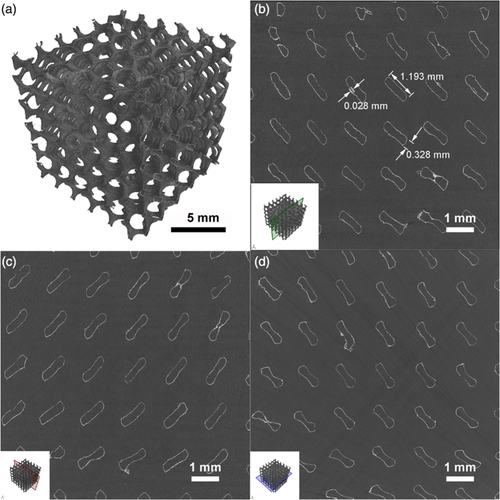

The feed spacers, designed and manufactured with the help of 3D printing to achieve complex geometries and sizes, are described most recently in the Journal of Membrane Science, by a team led by KU’s Dr. Hassan Arafat, Professor of Chemical Engineering and Director of CMAT. The team also includes professors Rashid Abu Al-Rub, Hector Hernandez and Giovanni Palmisano as well as researchers Oraib Al-Ketan, N. Sreedhar Navya Thomas and Mahendra Kumar. The KU team collaborated with Dr. Reza Rowshan, Executive Director of Core Technology Platforms Operations at NYU Abu Dhabi, to print the feed spacers using the 3D printer available at NYUAD’s Core Technology Platforms facility.

A patent has been filed on the new feed spacer design with the US Patent and Trademark Office.

“Feed spacers play an important role in promoting turbulence of the feed water, which then affects the water flux, an indication of how efficiently the water flows through the membrane, which has a direct impact on the power consumption in desalination plants, especially those that use reverse osmosis processes,” explained Dr. Arafat.

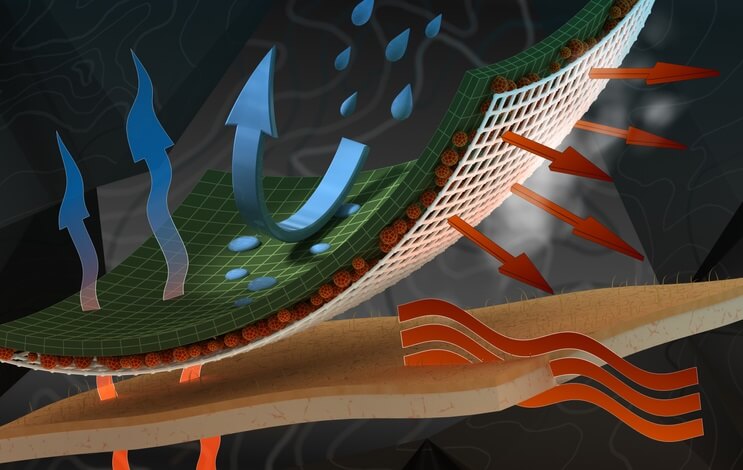

Reverse osmosis (RO) removes salt from seawater by pushing water under pressure through a semi-permeable membrane that allows water molecules through but blocks the dissolved salts. Because the water is being pushed at very high pressure to overcome its natural osmotic pressure, it consumes a lot of energy. More energy is required to overcome the issue of membrane fouling – when organic and inorganic deposits buildup on a membrane’s surface, reducing its ability to filter impurities.

Feed spacers are netted sheets made from strong polymer materials sandwiched between two membrane layers to create space for the water to flow through. Fouling usually occurs first at the feed spacers. The intersections where its filaments meet, known as ‘dead zones,’ provide nucleation sites for scaling and deposits of organic impurities or microbes. In addition to fouling, the overall design and geometry of the feed spacer also affects the water flux, or the flow of water through the membrane.

Traditional commercial feed spacers are planar, or flat sheets of netted plastics, which repeat the same diamond or rectangular shape – these are the feed spacer’s ‘cells’.

Dr. Arafat’s team took a different approach, realizing that additive manufacturing, or 3D printing, can be leveraged to produce materials with unique and precise pore geometrical configurations that can stand up to the rigors of high-pressure membrane desalination systems.

“The unique benefit of 3D printing over conventional manufacturing processes is its ability to fabricate structures with complex forms and shapes that can be optimized for fluid flow. This creates new applications for structures that we couldn’t use before the era of 3D printing,” Dr. Arafat explained.

One such class of complex geometries are triply periodic minimal surfaces (TPMS), which can be described mathematically as having perfectly curved surfaces with no self-intersecting or enfolded surfaces. TPMS have various properties that enable smooth fluid flow, making them ideal candidates for a number of applications in water research. ‘Triply periodic’ means that the structure can be patterned in the 3D space and ‘minimal surface’ means that it minimizes surface area for a given boundary.

“We theorized that the interconnected maze-like pathways of TPMS structures would enhance turbulence through the feed channel, while the perfectly smooth minimal surface would minimize pressure drop, as well as minimize locations for the attachment of foulants,” Dr. Arafat explained.

His theory proved true. After exploring a range of different configurations and shapes, Dr. Arafat’s team developed TPMS feed spacers that improved water flux by 16% using RO membranes and 38% using ultrafiltration (UF) membranes, when compared to a commercial spacer.

The feed spacers also proved to significantly reduce fouling. The team visualized fouling patterns on the membranes using crystal violet stains, which revealed significantly less biofilm depositions. The TPMS spacers showed a reduction in biofouling up to 91% compared to commercial feed spacers. Last but not least, due to their intrinsic curvature, the TPMS spacers were able to achieve higher flux and lower fouling while reducing the pressure drop – an energy consumption – in the feed channel. “This is the first time this combination of benefits has been demonstrated for a novel spacer design,” Dr. Arafat said.

3D printing allowed the researchers to print one contiguous feed spacer with interconnected repetitive cells, giving it a significant advantage over traditional feed spacers, which must be woven together and often lack precise conformity. With a greater level of control over the cell shapes, they were able to achieve curvature between the feed spacer’s cells, which improved the hydrodynamics of the feed spacer and increased its surface area; both of which contributed to an increase in water flow.

“Curvature creates turbulence within that structure, while a flat 2D structure creates more resistance,” Dr. Arafat explained.

“These spacers have shown great promise in enhancing both reverse osmosis and ultrafiltration processes, in terms of flux enhancement, energy consumption and fouling reduction,” he added. As a result, new applications of TPMS architectures are now being explored by the team, covering a range of potential applications in water and wastewater treatment.

The UAE relies on desalination plants for most of its potable water, which is why Dr. Hassan works to find new solutions aimed at making seawater desalination more efficient and sustainable.

Erica Solomon

Senior Editor

16 October 2019