A novel filtration device has the potential to filter wastewater much more efficiently and in an environmentally-safe manner, using 3D printing to manufacture structures based on fish gills.

Inspired by fish gills, a Khalifa University research team has developed a biomimetic on-chip filtration device to clean microplastics and oil droplets from wastewater. Their device is chemical-free and uses a 3D printing-on-membrane approach to develop a single device that mimics the shape and high surface area of fish gills at the microscale.

Prof. TieJun Zhang, Professor of Mechanical Engineering; Dr. Hongxia Li, Postdoctoral Research Fellow; Dr. Aikifa Raza, Research Scientist; and Dr. Faisal AlMarzooqi, Assistant Professor of Chemical Engineering; with Shaojun Yuan, Sichuan University; and Nicholas Fang, MIT, published their results in Scientific Reports.

Membrane filtration is a widely used technique with applications from the biomedical industry to environmental sciences. At its simplest, the water-filtration process sees purified water permeate through the membrane, while contaminants such as microplastics, oil droplets, and other soluble pollutants are stopped by the membrane. Some contaminants would accumulate on membrane surface, or get trapped in membrane. This trapping is the major bottleneck in effective water filtration, as, over time, the membrane becomes clogged with the separated particles.

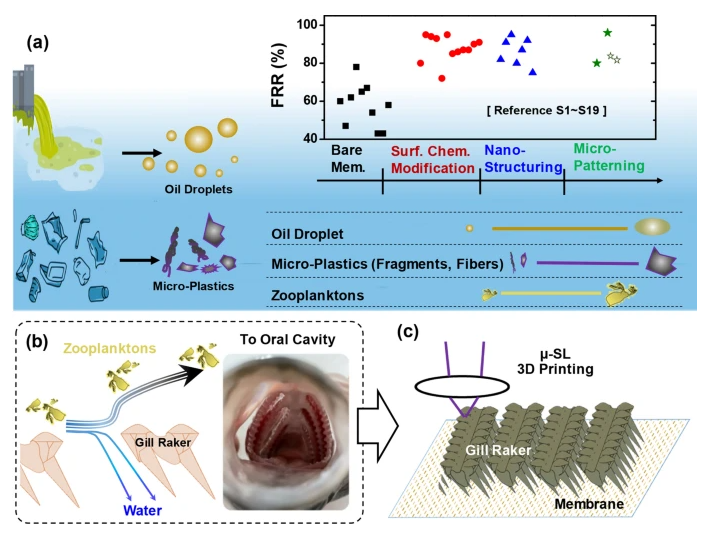

Most solutions to overcome membrane clogging focus on developing novel materials or modifying the surface of the membrane, using metal oxides and photocatalytic materials to repel contaminants and prevent the membrane from degrading. However, such chemical approaches may be easy to implement and effective, but environmental concerns have been raised around their use in nature.

Many fish species feed by filtering food particles from huge volumes of water without clogging their oral filters. Their mouths contain structures called gill rakers, which work much in the same way that a spaghetti strainer or coffee filter functions: Water is forced through the pores of the filter, trapping the desired particles.

“Surface patterning and creating topological structures on membrane surfaces can manipulate the local hydrodynamics and prevent clogging on the membrane,” Prof. Zhang said. “With properly designed surface structures, the flow of water near the membrane surface can be controlled to inhibit the deposition of particles that would clog the membrane. For this, surface geometry is the key.”

Different surface structures like grooves and pyramids have demonstrated anti-fouling properties. Fish gills present these structures but they are remarkably complex, and replicating them is made possible only with emerging 3D printing techniques. Recent advances in micro-stereolithography 3D printing have made it possible to fabricate complex structures at the microscale, but it is still challenging to fabricate these surface architectures and membranes with nanometer pores at one-step, and usually, the nanoporous membrane has to be manufactured separately. With the new direct-printing on membrane technique used by the research team, the filtration membrane and complex surface structures can be integrated as an all-in-one device, making it the first of its kind for filtration purposes. A patent has been filed for this technique, towards its commercialization.

The team developed the device, mimicking fish gills, to filter wastewater containing microplastics and oil droplets, as one of the most challenging problems in wastewater treatment and ocean pollution control. Gill raker-shaped structures were printed directly onto the membrane surface, with the final device integrating all the functional components of a filter.

“We developed a microfluidic filtration device,” Dr. Li said. “When we tested it against oily water and wastewater with microplastics, we found that the extraordinary anti-fouling performance of a fish gill-structured membrane originates from the unique flow behavior of the oil droplet and plastic microparticle during the filtration process. As the water containing the droplet/particle approaches one of the gill structures, the forces acting on the water cause the droplet/particle to ‘ricochet’ away, and thus avoid oil droplets or microplastics contaminating the membrane surface. In this way, even though the droplet/particle size is much smaller than the gap between two neighboring gill structures, it cannot pass through the gap and remains in the main flow of water. This means that only clean water passes through the membrane and the filtration device does not become clogged with contaminates.”

The potential application fields of printing on membrane are myriad and diverse, with membranes in microfluidics one of the most important. Integrated with the enormous variety of materials, morphologies, and design options, the ”print-and-play” microfluidic membrane devices can be readily tailored to other emerging energy, chemistry, bioengineering, and medical applications.

Jade Sterling

Science Writer

19 July 2022