KU researchers publish the first ever review paper on layered graphene for strain and pressure sensor applications

A class of nanomaterials known as cellular graphene are emerging as a promising avenue for developing more efficient, flexible and wearable strain and pressure sensors. However, a strong understanding of how to best develop cellular graphene with highly tailored mechanical properties for optimal pressure and strain sensing capability has been lacking, until now.

A team of researchers from Khalifa University and the University of Cambridge, led by KU Professor of Aerospace Engineering Dr. Kin Liao, has written the first-ever comprehensive review paper on the design and development of cellular graphene for the application of strain and pressure sensors. Their paper was published earlier this month in the journal Matter by Cell Press.

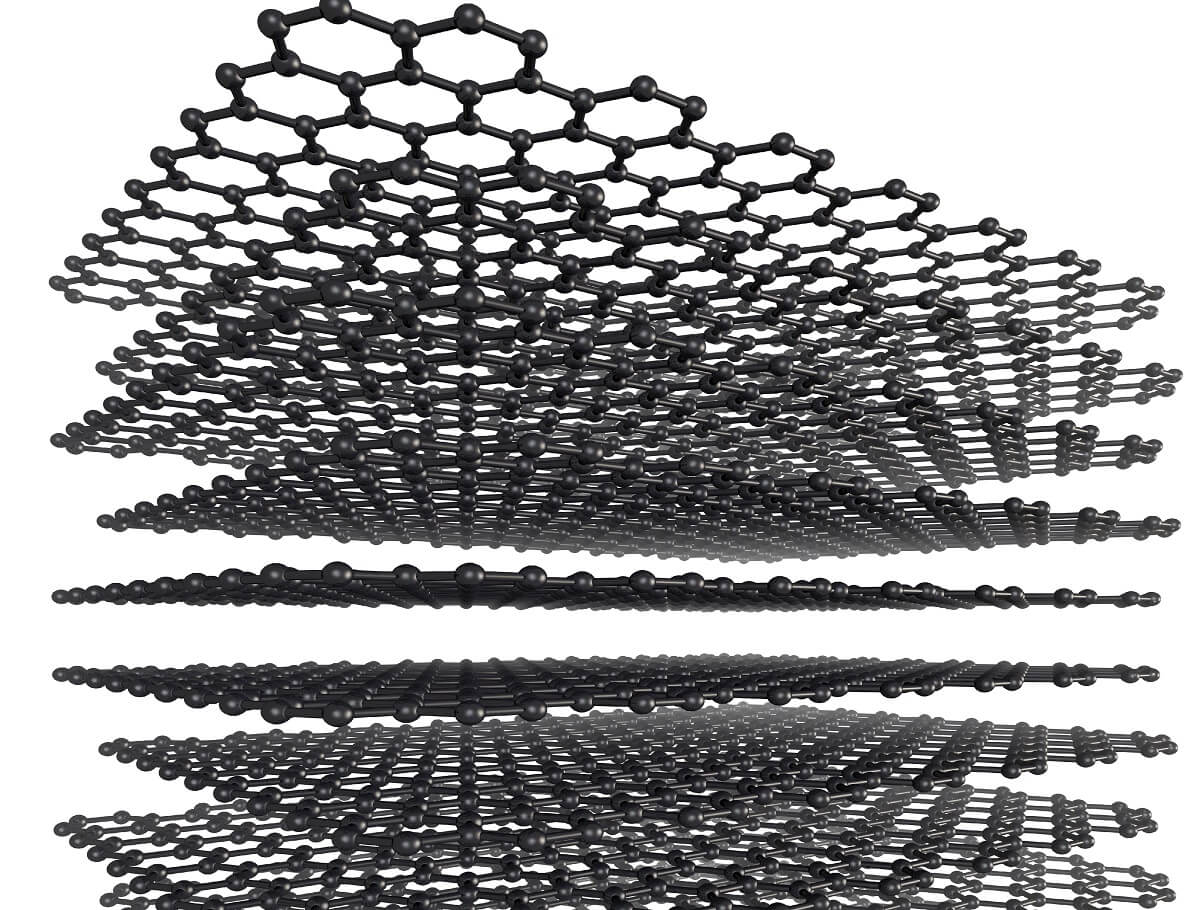

Graphene is an ultrathin 2D material that possesses incredibly unique properties. It is the thinnest, strongest material known to exist and can conduct heat and electricity better than perhaps any other material. However, it is difficult to translate graphene’s 2D strength into useful 3D applications, like sensors. In response, researchers have been figuring out how to manipulate graphene to create three-dimensional representations of it.

“Graphene is a 2D material, like a sheet of paper,” explained Dr. Liao. “When one assembles these tiny sheets in a three-dimensional form, like a sponge, it becomes cellular graphene, also known as graphene foam or graphene sponge. Cellular graphene are structures deliberately designed and processed from graphene sheets. This kind of meta-material has properties that can be actively designed for a variety of applications.”

One application that cellular graphene is particularly well suited for is strain and pressure sensing. By converting very small changes in pressure into larger, significant changes in an electrical current, pressure sensors have a wide range of applications. They are used in a number of personal devices and biomedical devices, and for industrial monitoring, navigation, and ultrasonic imaging.

“Cellular graphene is an extremely promising candidate material for the type of flexible, wearable and ultra-sensitive strain and pressure sensors needed to support emerging applications, particularly in healthcare technology,” Dr. Liao shared. “For example, strain and pressures sensors with high sensitivity and a large sensing range are critical for the accurate measurement of human physiological parameters, such as subtle microcirculation dynamics or whole body movements.”

“Traditional metal-based strain and pressure gauges do not satisfy these emerging requirements because of their outdated design and less effective sensing mechanisms. Therefore, nanomaterials like carbon nanotubes, graphene, and metallic nanowires and nanoparticles, have been applied in the design and fabrication of novel strain and pressure sensors over the last few years.”

The demand for smaller, more sensitive and more reliable strain and pressure sensors that may be incorporated into emerging technologies like biomedical sensors is growing rapidly. The worldwide pressure sensor market is pegged to reach US$11.4 billion by 2024.

Dr. Liao’s paper aims to uncover some of the major challenges currently facing the development of cellular graphene-based strain and pressure sensors, which include issues of precise control of the cellular structure, as well as achieving durability and stability.

The paper is a significant contribution to the research community and to the advancement of cellular graphene-based sensors, as it consolidates the most recent research findings from around the world and critically analyzes a spectrum of different cellular graphene fabrication processes, systematically comparing the fabrication method against the materials’ strain and pressure sensing performance.

The review paper is a result of the research work that has been carried out by Dr. Liao’s research group over the past few years. The main research interest of his group is 2D and 3D assembly of heterogeneous two-dimensional materials (including graphene), and their advanced applications in strain- and pressure-sensing, electromagnetic interference shielding, and electrochemical energy storage. Currently a team lead by Dr. Liao and Dr. Rashid Abualrub, Interim Chair and Professor of Aerospace Engineering, is developing cellular graphene lattice, or intricately designed microstructures built by graphene sheets, derived from 3D printed scaffolds.

Most importantly, the paper points out that future research efforts should focus on in-depth understanding of structure-property-function correlations of cellular graphene-based sensors and generalization of design principles to be applied during fabrication of other 2D materials-based sensors. (“Structure” refers to whether the cellular graphene consists of struts or spherical cells or cells of other geometry, in micrometer scale; “property” refers to thermo-electro-mechanical properties that depend on or are derived from a specific structure of the foam, such as a closed spherical cell structure; and “function” refers to how those properties can be utilized to make something useful, such as sensors.)

The potential applications of cellular graphene and 2D materials are diverse. Thus, Dr. Liao’s review will benefit a broad range of researchers in the UAE and around the world on future research directions in strategic areas not only in strain sensing and biomedical applications but also in energy storage.

Erica Solomon

Senior Editor

13 November 2019