Sustainable fuels are within reach but processes need to be optimized for low-cost industrial scale production. Converting hydrogen and carbon dioxide into methanol for sustainable fuel is one route, but the reaction pathway needs elucidating and catalysts optimizing. A team of researchers from Khalifa University has developed a model to do just that.

Transforming carbon dioxide emissions into value-added products like methanol for fuel is essential for the development of a circular economy and reducing anthropogenic impact on the atmosphere. But the process of developing these products can introduce side reactions that can significantly influence efficiency and the quality of the final product. Modeling tools, therefore, are crucial to predicate and understand the reaction pathways to improved operating conditions or catalyst design.

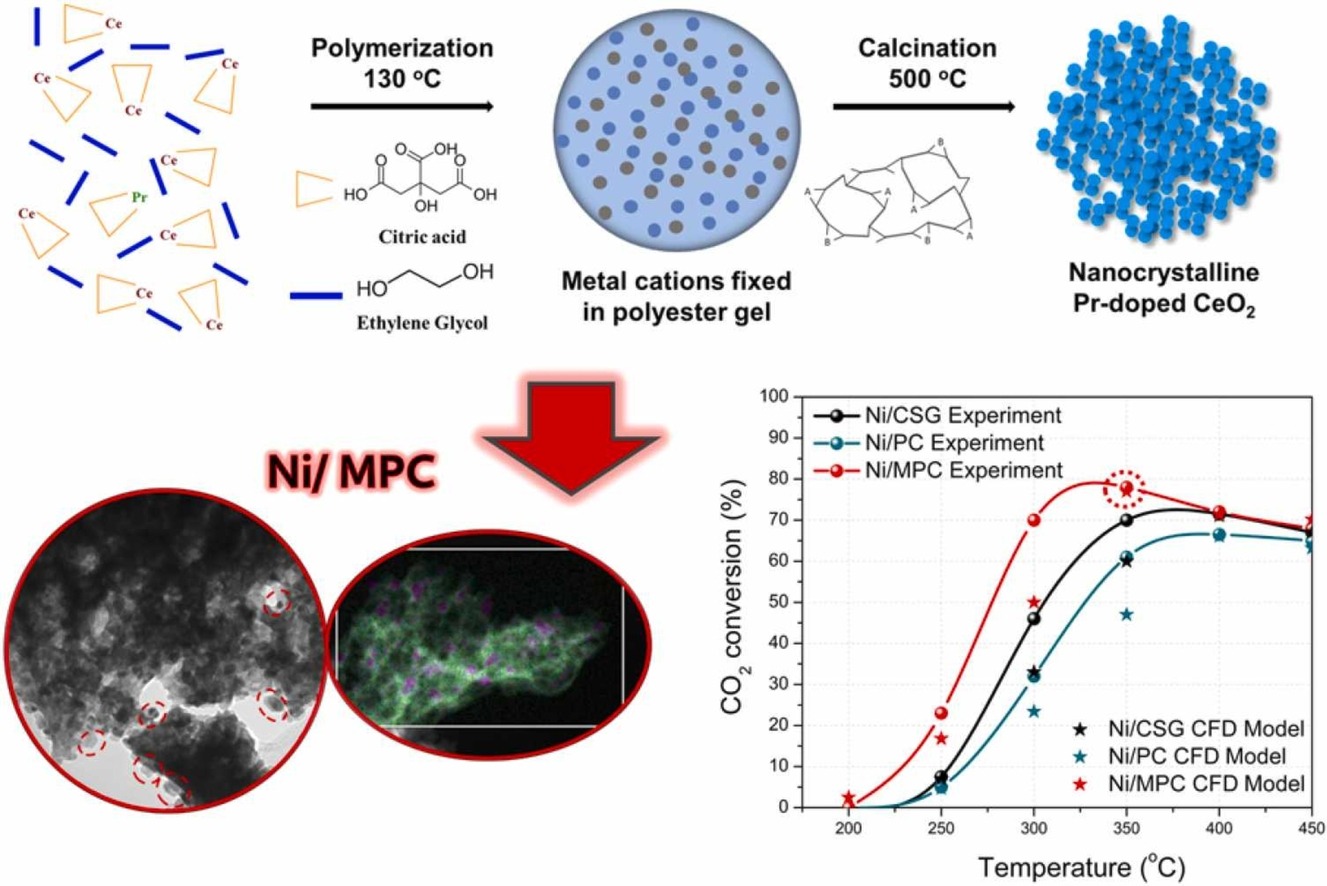

A team of researchers from Khalifa University has developed a new practical modeling approach to examine the conversion of carbon dioxide and hydrogen to methanol using a copper-based catalyst. Their model offers a reliable tool for revealing the role of active sites that may control the performance of a CO2 hydrogenation catalyst.

Dr. Kaisar Ahmad, Postdoctoral Fellow, Dr. Maguy Abi Jaoude, Associate Professor, Prof. Kyriaki Polychronopoulou, Director of the Khalifa University Center for Catalysis and Separation (CeCaS), and Dr. Florent Ravaux developed the model and published their results in Fuel.

“Renewable methanol can play an important role as a feedstock in the production of lower-emission fuels,” Dr. Abi Jaoude said. Producing green methanol from CO2 and renewable hydrogen is an effective alternative to biomass conversion, she said, adding that “it can meet global decarbonization objectives without endangering food security.”

There are several pathways to creating sustainable fuels that involve processing and treatment of lipids, synthesis gas and alcohols. In the production of methanol, the common route is via synthesis gas with very low amounts of carbon dioxide. However, hydrogenation of carbon dioxide would be a more sustainable process, but the mechanism behind the conversion remains a subject of debate.

Researchers have proposed two pathways for methanol production from carbon dioxide and hydrogen, and understanding how this process works will allow more effective and efficient catalysts to be developed.

“In chemical kinetics, key pathways that govern the reaction mechanism at a catalyst’s surface are predicted based on its physicochemical properties,” Dr. Kaisar and Dr. Abi Jaoude said. “Understanding the kinetics on a particular surface of a catalyst for a specific reaction can assist in designing a new and improved catalyst.”

Determining the pathways and kinetic activities is time-consuming in the lab. Experimental evaluation is also expensive and a tedious endeavor, but modeling approaches can generate results much more quickly and easily.

The KU research team wanted to find the minimum energy pathway for methanol synthesis and derive its kinetic expression. They chose to investigate a catalyst made from copper, zinc oxide and chromium oxide. Copper is a more effective catalyst in the presence of metal oxides, and the zinc and chromium oxides aid in increasing catalyst activity, enhancing its performance in the hydrogenation process.

Their practical model predicted the minimum energy pathway and their simulations with experimental data confirmed the model’s accuracy. Their outcomes were consistent with documented reports, confirming the validity of the proposed modeling method.

“By developing a kinetic model for the most favorable pathway based on the activation energy and interactions of molecules on the catalyst surface, an in-depth understanding of the surface science and kinetic parameter dependence on the catalyst can be obtained,” The research team said. “Our practical model can be used to study the kinetics of catalytic reactions targeting sustainable fuels or their precursors at reduced cost and time.”

Jade Sterling

Science Writer

17 January 2023