Model Helps Make Better Predictions about Mechanics of Acid Fractured Horizontal Wells and Oil Flow

Fracturing, commonly known as fracking, is frequently used to enhance oil and gas production from underground hydrocarbon reservoirs. Fracking allows access to vast quantities of previously unreachable unconventional hydrocarbon resources and therefore is being adopted by regional oil and gas producers to unlock oil and gas deposits. For instance, the Abu Dhabi National Oil Company (ADNOC) saying fracking will be critical to future production.

To support ADNOC’s ambition to explore new sources of oil and gas, researchers at Khalifa University, Dr. Talal Al Hajeri and Dr. Mohamed Motiur Rahman, have developed a new computer model that could potentially boost oil production from unproductive, or ‘tight’, carbonate reservoirs by making better predictions about the mechanics of acid fractured wells and how oil flows through them.

The model was described recently by Dr. Talal Al Hajeri, Director Engineer of the UAE Navy Task Force and PhD student from KU, during a technical seminar at the 2019 Abu Dhabi International Petroleum Exhibition and Conference (ADIPEC).

“The main objective of this work is to study the behavior of injected hydrochloric acid and oil flow from a horizontal well with multi-stage acid fractures,” explained Dr. Al Hajeri.

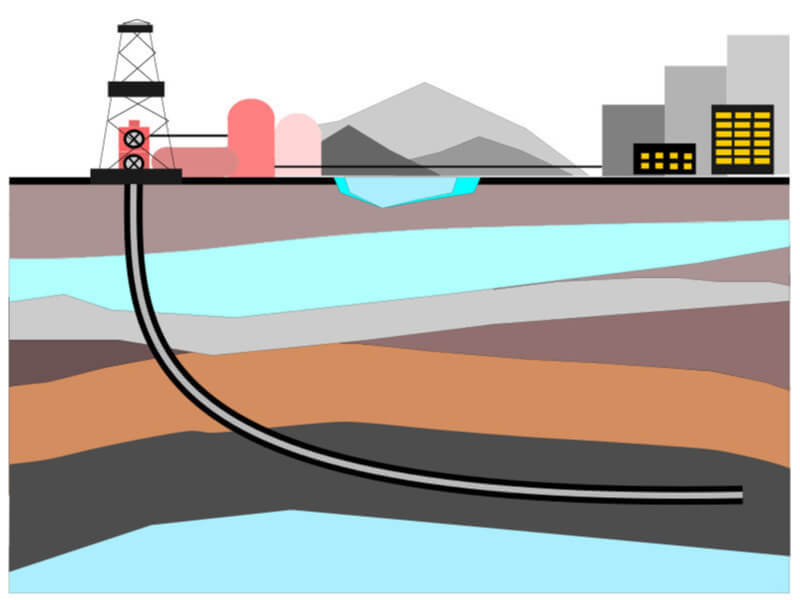

Horizontal wells, which are created by horizontal drilling, combined with acid fracturing, allow oil companies to access previously non-viable reservoirs. In conventional vertical wells, a single acid fracture is used, but in horizontal wells, multiple acid fractures are required.

“Our research looks at the acid flow behavior in multiple fractures created hydraulically in horizontal wells, and the flow of the oil after the fracturing. We have created an integrated model that simulates five different stages of fractures, along with other dimensions, such as well geomechanics and operational constraints. The model then generates the post-fractured oil flow and production yields,” Dr. Al Hajeri said.

Because fracturing takes place underground, using advanced computer models to simulate the fracturing mechanics is critical to understanding and improving the process. Dr. Al Hajeri and Dr. Rahman’s work will contribute to advanced well simulation techniques of acid fracturing that are representative of actual field applications.

Acid fracturing is one of two types of fracturing methods used to exploit tight and ultra-tight (or low permeability) oil formations underground. In carbonate rock formations, such as limestone and dolomite, which make up the geological landscape of the Middle East, acid fracturing is common. Whereas in sandstone formations, hydraulic, or proppant, fracturing in used.

Both techniques involve injecting high-pressure liquids into an oil or gas rock formation to create a flow channel through which hard-to-reach hydrocarbons trapped in porous rocks can flow to the surface.

Hydraulic fracturing involves pumping high-pressure liquids (like water) mixed with a proppant (such as sand) into a well to crack the rock open (the proppant is used to keep the cracks open). While acid fracturing involves pumping high-pressure acids (like hydrochloric acid) into a well to etch channels in the rocks (in acid fracturing, the acid keeps the channels open).

Before fracking can begin, reservoir modelling is key to improving productivity, as it allows operators to better understand their resources, the area they’ll be working in, and the best locations to drill. Even more helpfully, whether acid fracking or hydraulic fracking should be used can also be determined digitally.

“Determining the type of stimulation technique for a formation is completely dependent on instinct, logic, and experience,” said Dr. Al Hajeri. “Moreover, choosing between hydraulic or acid-based fracturing may be subject to regulations, environmental, or even geological criteria.”

Modelling can help make this decision. Computational fluid dynamics (CFD) is a branch of fluid mechanics that uses numerical analysis and data structures to analyze and solve problems involving fluid flows. Computers are used to perform the calculations required to simulate the free flow of the fluid, and the interaction of the fluid with surfaces defined by boundary conditions. The researchers used the Autodesk Fusion 360 software to initiate the vertical and horizontal fractures before using CFD to model the flow inside the fracture itself. There are several studies using various CFD software to investigate hydraulic fracturing but these involve the application of proppant, not the use of an acid.

“The issue with using CFD software for acids compared to proppant is that the properties of acid are normally not included in the CFD directory compared to the mechanical properties which can be added for solid flow,” explained Dr. Al Hajeri.

The researchers focused on a preliminary simulation to model acid fracturing in a carbonate formation. They combined two of the most common hydraulic fracture models: the 2D fracture geometry model known as the Perkins-Kern-Nordgren (PKN) model and the pseudo 3D fracture geometry model. The outcomes of this combined model will assist in upscaling simulations to 3D models with field values from existing wells, adding validity. Further developments with fracture simulation can be carried out for horizontal fractures to understand how the area around the fracture will be affected.

“One of the challenges of acid fracturing in carbonates is related to layering where it is important for the induced fracture not to propagate into adjacent undesired layers,” said Dr. Al Hajeri. “The CFD simulation gives a visual representation of acid and oil flow inside a fractured formation and how fluid flow properties affect the development of acid turbulence inside the fracture and along the fracture walls. Additionally, the fracture widening for a horizontal fracture is simulated to model the stress intensity on fracture growth and the displacement of the mesh elements.”

“Our simulation can show the behavior of two fracture models and their relative geometries where most realistic formation constraints and requirements are incorporated. If the model is integrated properly with production models for designing an acid fracture, this can predict the production profile in a much better way than any existing model in the industry.”

Jade Sterling

News and Features Writer

18 November 2019