Dr. Kyriaki Polychronopoulou, Professor of Mechanical Engineering and Director of the Center for Catalysis and Separations (CeCaS) at Khalifa University, and her research group have recently authored a paper on dry reforming of methane that was published in the prestigious journal Applied Catalysis B: Environmental, with an impact factor of 19.5 (Elsevier, Q1).

The KU research group was led by Dr. Polychronopoulou and included Aseel Hussien, PhD Student, Dr. Aasif Dabbawala, Postdoctoral Fellow and co-advisors Dr. Maryam Khaleel, Assistant Professor of Chemical Engineering, and Dr. Dalaver Anjum, Assistant Professor of Physics. This work was the result of a fruitful collaboration with the University of Cyprus team led by Prof. A.M. Efstathiou.

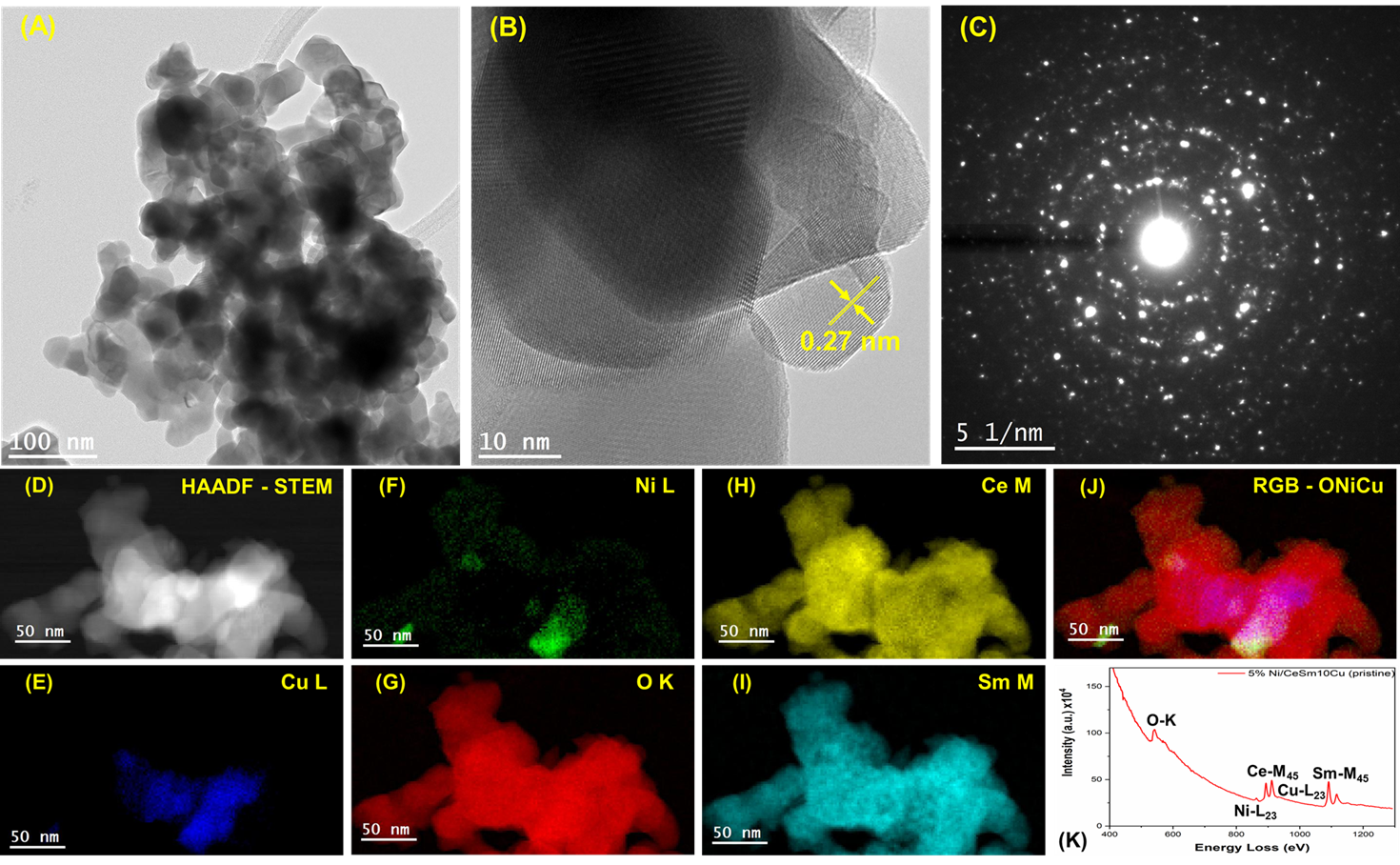

The paper, titled “Elucidating the role of La3+/Sm3+ in the carbon paths of dry reforming of methane over Ni/Ce-La(Sm)-Cu-O using transient kinetics and isotopic techniques” highlights the different effects of the presence of dopants such as La3+ and Sm3+ heteroatoms in the performance of a Ni catalytic system towards the dry reforming of methane (DRM) reaction.

Emphasis is given on the carbon deposition and their removal reaction paths in the dry reforming of methane (DRM) at mid-high temperature (750 °C) utilizing transient kinetic and isotopic experiments.

Coke deposition is the most critical challenge for DRM reaction and the bottleneck for its industrialization.

The role of lattice oxygen is highlighted, especially when it comes to the deposited carbon oxidation by lattice oxygen of support and that by oxygen derived from CO2 dissociation under DRM reaction conditions; both rates were quantified.

Ni nanoparticles (23-nm) supported on La3+-doped catalyst exhibited at least 3 times higher initial rates of cleaning the surface through carbon oxidation to CO by lattice oxygen, and ~ 13 times lower rates of carbon accumulation than Ni (18-nm) supported on Sm3+-doped catalyst.

The concentration and mobility of labile surface oxygen at the Ni-support interface region seems to correlate with carbon accumulation.

Another important finding was the in situ formation of Ni-Cu nano-alloy as Cu from the support was found to diffuse under reaction conditions to the metal-support interface and being alloyed with Ni. This was found to be partly responsible for lowering carbon deposition and increasing carbon oxidation rates to CO.