Project in Collaboration with Abu Dhabi Municipality for Testing of Five Different Asphalt Mixtures in Response to UAE’s Surface Transport Master Plan 2030

View this post on Instagram

Khalifa University has announced that a team of researchers at its Department of Civil Infrastructure and Environmental Engineering have developed a new asphalt mixture with recycled tires that can reduce the pavement’s environmental footprint and cost. This asphalt is already laid on a stretch of two kilometers of the traffic-heavy E30 Abu Dhabi–Al Ain Truck Road, for preliminary trials.

With the challenges posed by climate change and a rapidly growing population, there is a pressing need for more economically and environmentally sustainable asphalt mixtures that can withstand rising temperatures and a higher number of vehicles on the road. The energy required to extract, produce, and refine paving materials is a huge contributor to the carbon footprint of road construction.

The project aims to replace the proprietary and costly synthetic polymers used to produce Polymer Modified Bitumen (PMB) – a basic component of asphalt pavements used around the world today – with ‘crumb rubber’, which consists of rubber particles produced by grinding end-of-life tires. Only superior quality polymers are utilized for tire production, hence, despite its much lower cost, the resulting bitumen, called Crumb Rubber Modified Bitumen (CRMB), has mechanical characteristics similar to, if not better, than PMBs.

Dr. Arif Sultan Al Hammadi, Executive Vice-President, Khalifa University, said: “Sustainability is a top priority for Abu Dhabi. We, at Khalifa University, are committed to supporting Abu Dhabi’s goal to reduce its carbon emissions, protect its environmental resources. Building sustainable pavements is an important way to achieve this goal, as it will minimize the use of natural resources, reduce energy consumption, cut greenhouse gas emissions and pollution, while improving road performance and supporting Tadweer’s goal to recycle 75% of the waste produced in Abu Dhabi by 2021.”

Eng. Issa Mubarak Al Mazrouei, Executive Director, Infrastructure and Municipal Assets Sector, Abu Dhabi Municipality, said that this project comes under the existing partnership framework with Khalifa University, and its first fruits were the establishment of the National Center for Infrastructure Research. The NCIR aims to achieve the vision of sustainable development and supports innovation initiatives that provide environment-friendly solutions, based on scientific foundations and economic feasibility. Al-Mazrouei pointed to the launch of a new joint study with Khalifa University for updating and developing specifications and design standards for the asphalt mixtures that are suitable to the local environmental conditions and the natural materials available in the UAE.

The joint project team is led by Dr. Tom Skarpas, Professor and Chair, Civil Infrastructure and Environmental Engineering, Dr. Michele Lanotte, Assistant Professor, Dr. Jamal Elzarif and Eng. Saleh Hamed Al Jufri from the Abu Dhabi Department of Municipal Infrastructure and Assets.

Dr. Lanotte explained that about 650 tires can be recycled to build one km of single lane of a roadway. This technology can contribute significantly to the reduction of the UAE stockpiles of scrap tires, reduce the energy footprint of Abu Dhabi’s pavement and improve the performance of the local road network. Hence, pavements constructed with CRMBs are not only financially attractive but also environmentally-friendly since they provide a solution to the critical problem of tire disposal.

The project was initiated in response to the UAE’s Surface Transport Master Plan 2030, which aims to create conditions for sustainable road infrastructure development by using resources responsibly, minimizing pollution and preserving Abu Dhabi’s unique environment.

Five different asphalt pavements were laid between October and November 2019 on the E30 Highway, with the support of the industrial partners Richmond Petroleum, Tarmac-Colas and Al Sahraa Group. Two asphalt mixes were designed with CRMB, two with a commercially available PMB and one with a traditional unmodified bitumen.

In Abu Dhabi alone, more than 7,000 tons of used tires were produced in 2018 and only partially recycled for the local rubber industry, which has necessitated a quick management solution to avoid the creation of an unmanageable amount of rubber waste.

During construction, the field crews noticed that both asphalt mixtures containing CRMB exhibited greater ease of compaction compared to the other mixtures, which resulted in less or no use of some of the field compaction equipment that was instead necessary for the other mixtures. “The project outcomes are extremely optimistic since they lead to positive impacts on the work crews as well as the total cost and time of construction,” Dr. Skarpas said.

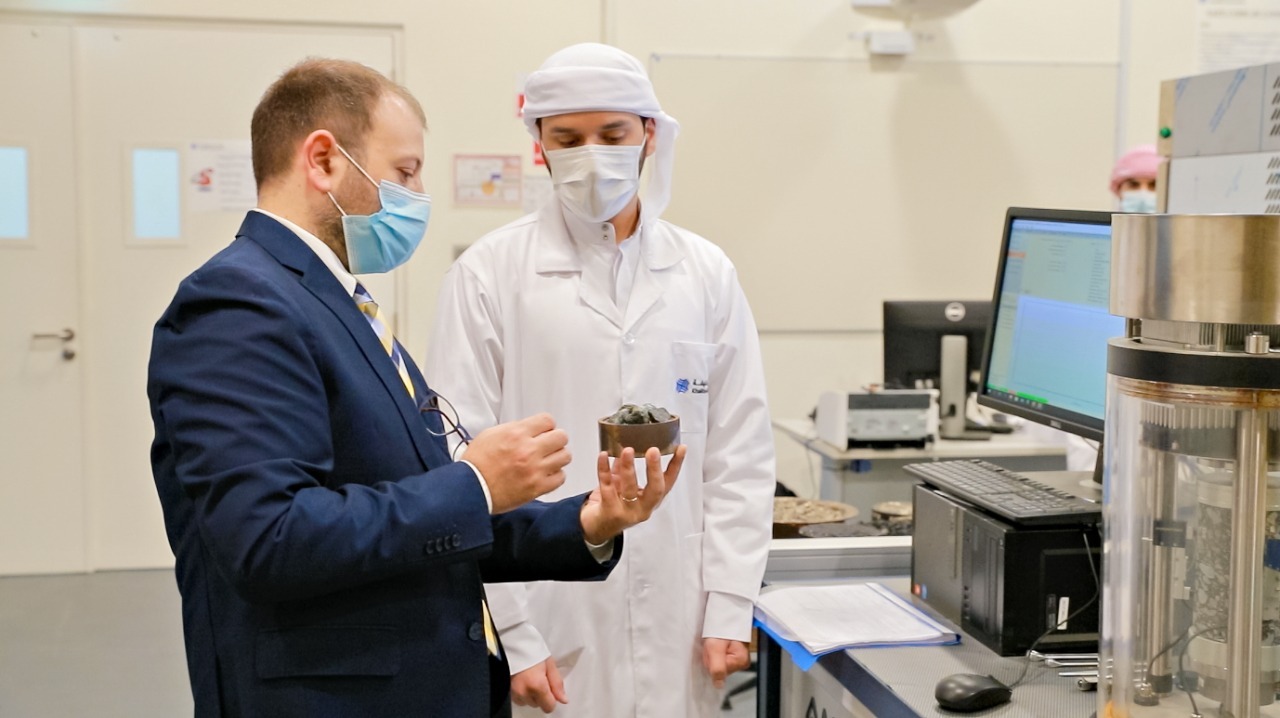

The asphalt mixtures were sampled during construction and are currently under testing and evaluation at the Khalifa University Infrastructural Materials Laboratory. Various aspects of the mechanical response of CRMB-based asphalt mixtures like resistance to permanent deformation and fatigue cracking are currently being evaluated through the lab’s state-of-the-art testing equipment. The goal is to compare the response of CRMB asphalt mixtures to that of other locally available and currently utilized asphalt mixtures.

The performance of the asphalt in the E30 highway will also be monitored under traffic conditions over the next few years under the joint supervision of the Abu Dhabi Municipality and the Khalifa University Pavement Engineering team. The outcome of this joint initiative will be the development of specifications for the Municipality for the implementation of the CRMB asphalt throughout Abu Dhabi.

By leveraging a major waste stream in Abu Dhabi, Khalifa University is helping to prevent tires from piling up in landfills, while creating a high-value technology for more sustainable, economically viable roads in the UAE.

Clarence Michael

English Editor Specialist

4 October 2021