Understanding the role of the surfaces and internal structure of the nanocrystal will help researchers develop more effective and efficient catalysts for many important catalytic processes.

A catalyst is a substance that can be added to a reaction to increase the reaction rate without being consumed in the process. They typically speed up the reaction by reducing the energy needed to activate the reaction or by changing the mechanism by which the reaction occurs. Catalysis is one of the pillars of the chemical industry, so developing effective and efficient catalysts for a wide range of uses is crucial.

Prof. Kyriaki Polychronopoulou, Professor of Mechanical Engineering and Director of the Khalifa University Center of Catalysis and Separation (CeCaS), used an advanced form of imaging to analyze the structure and electronic properties of an engineered nanoparticle that is considered one of the emerging candidates for use in catalysis.

With Dr. Yasser Al Wahedi, Assistant Professor, Dr. Vijay Wadi, Research Scientist, Xinnan Lu, and Marios Katsiotis, all from Khalifa University, the findings were published in Nature Communications. The Khalifa University team collaborated with researchers from Stockholm University in Sweden, the Greek National Center for Scientific Research, and the Korean Electron Microscopy Research Center.

This research was also selected by the editors at Nature Communications to be featured in an Editors’ Highlights webpage of recent research called ‘Materials science and chemistry.’ The Editors’ Highlights pages showcase the 50 best papers recently published in a particular area of science.

“Nanocrystalline materials have been a hot research topic thanks to their use in many important applications from catalysis, to energy conversion and storage, and drug delivery,” Prof. Polychronopoulou said.

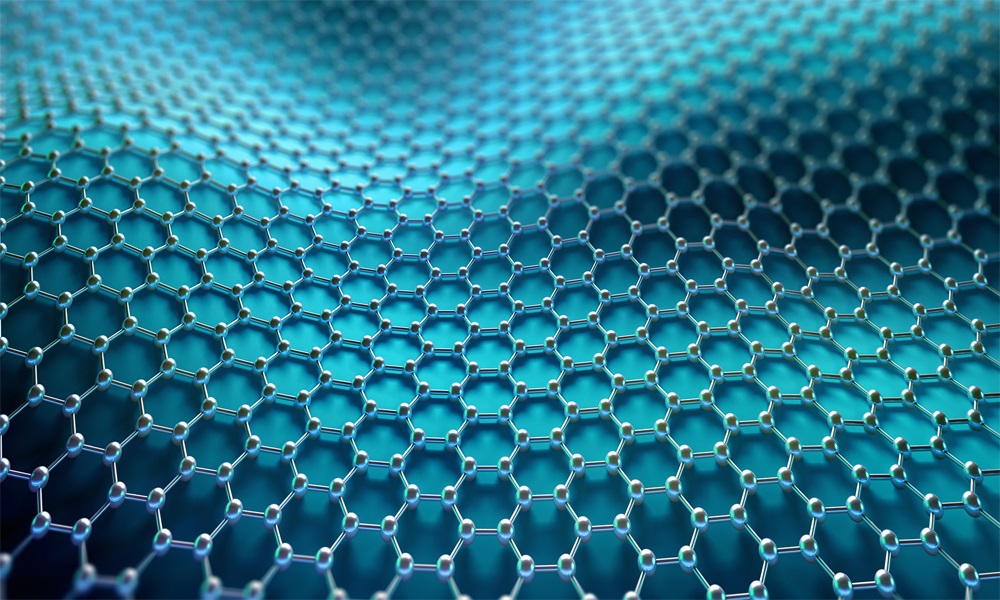

Ultrafine and comprising crystals as small as a single nanometer, or a billionth of a meter, nanocrystyalline materials can be tailored by controlling the size and structure of the crystals and the morphology of the material’s surface. This is particularly useful in catalysis, as scaling down the particle size increases the number of sites available for the reactions to take place, but also modifies the material’s electronic properties. Additionally, catalytic reactivity and selectivity can be enhanced by modifying the arrangement of the surface atoms.

The crystals in these materials must be grown through chemical reactions to create the desired structures, with the atoms, molecules and ions assembling into a crystal structure one after another on the growth surface. Once created, these materials are approximately half crystal and half interface, ready for use in many applications. For Prof. Polychronopoulou, that use is catalysis.

However, the stability of Ni2P nanocrystals depends on their experimental synthesis conditions, and this dependence is not well understood. Prof. Polychronopoulou’s research found that when there is excess phosphorous during the synthesis, the nanoparticles come out with hexagonal rod-like shapes.

The underlying symmetry of the resulting crystals can be seen in the facets that appear on the surface. Facets are flat surfaces on geometric shapes: think of gemstones, which commonly have facets cut into them to improve their appearance by allowing them to reflect light. In grown crystals, the facets are a consequence of the material and the surface energy, as well as the general conditions under which the crystal formed.

An inherent challenge in using any material for catalysis is how to access the catalytic sites generally confined inside the structure. In producing Ni2P crystals, Prof. Polychronopoulou’s research combined chemistry with calculations to define the reaction parameters to grow the ideal crystal with the predicted facets and electronic structure.

“It is extremely difficult to manufacture nanostructured materials,” Prof. Polychronopoulou said. “Using advanced calculations, we predicted the structure of the crystals and experimentally verified the crystal facets and structure using nanocrystallography.”

Nanocrystallography is a technique used to analyze the diffraction patterns of a crystal targeted by a beam of electrons. After studying the nickel phosphide nanocrystals that Prof. Polychronopoulou grew using nanocrystallography, her team found that the nanocrystals comprised a variety of surfaces, with three primary facets exposed.

The team then used another advanced technique, known as solid-state nuclear magnetic resonance imaging, to probe the nanocrystal further and determine the distinct surface facets, while also experimentally proving that their calculations and predictions were correct.

Solid-state nuclear magnetic resonance spectroscopy is an atomic-level method to determine chemical structure, 3D structure, and dynamics of solids. It is sensitive to the structure and electronic environment at the atomic scale, and is able to distinguish between the surface facets and the interior of the nanoparticles.

“This is the first time that facet analysis of a transition metal nano-sized catalyst and the relevant electronic changes were experimentally verified, demonstrating that solid-state nuclear magnetic resonance nanocrystallography is an emerging tool in the study of metal nanocatalysts,” Prof. Polychronopoulou said.

Jade Sterling

Science Writer

23 September 2021