CO2 Capture and Utilization Lab

The CO2 capture and utilization lab in RICH specializes in developing cutting-edge technologies to capture CO2 emissions directly from industrial processes, transforming them into high-value products through innovative utilization methods. As a strategic direction, the RICH center focuses on the development of advanced carbon capture technologies by investigating novel and more efficient materials and processes for CO2 capture. RICH activities in this area include emerging aqueous and organic solvents (DES, lean water, IL), novel solid adsorbents and hybrid systems. Moreover, projects that turn captured CO2 into materials like biofuels, building materials, or even pharmaceuticals are being investigated for the potential of carbon reuse. In th CO2 Capture and Utilization Lab, a range of specialized equipment designed for efficient carbon capture, processing, and utilization may be found.

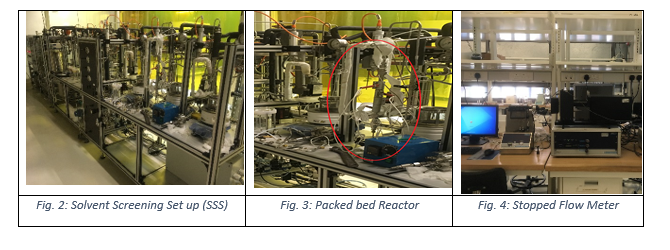

Here are some major pieces of equipment:

- Solvent Screening Setup

- The Vapor Liquid Equilibrium (VLE) setup

- Packed bed reactor

- Stopped flow meter

- Intelligent Gravimetric Analyzer (IGA)-ABR-DSMS

- 3 Flex Multiport Physisorption/Micropore Analyzer