New, More Robust Optical Fibers for Temperature Sensing Possible with Additive Manufacturing

Using polymers embedded with color-changing powders, the Khalifa University research team developed an optical fiber that can be 3D printed to sense temperature and remain strong enough for use in the most rugged environments.

A variety of electronic sensors are used for temperature sensing in farming, chemical engineering, medical diagnostics, power generation and pipelines. These sensors are well-developed and widespread but are susceptible to faulty readouts in harsh environments.

Dr. Haider Butt, Associate Professor of Mechanical Engineering, Dr. Fahad Alam, Postdoctoral Fellow, Dr. Mohamed Elsherif, Postdoctoral Fellow, and Ahmed Salih, Research Assistant, have developed a polymer-based optical fiber that can be manufactured using 3D printing to measure temperature. They published their results in Additive Manufacturing.

Optical temperature sensors are based on fiber-optic technology. They can be operated in a wide temperature range, do not require electrical cables and are resistant to electrical and magnetic disturbances. Optical fibers are typically made by stretching glass or plastic to a diameter slightly thicker than that of a human hair, which makes them structurally fragile.

“Optical fiber sensors can work in harsh environments as they are immune to electromagnetic interferences and have remote sensing capabilities,” Dr. Butt said. “They show high sensitivity but they do have durability issues and are prone to be affected by small mechanical disturbances. Polymer fiber-based sensors could be an alternative solution because of their robust strength and efficiency. They are also unaffected by ambient disturbances. Polymer-based fibers exhibit low sensitivity, but they are relatively accurate and reusable.”

Polymer-based fibers also offer the opportunity for highly tuned production via additive manufacturing. 3D-printed fibers can be designed and created for highly specific purposes, paving the way to expand their prospects for research as well as commercial purposes. To achieve multi-functionality, stimuli-responsive materials can be added to the resin used to print the sensors. When external triggers interact with these materials, they induce changes in the physical or chemical properties of the sensor, which can be quantified.

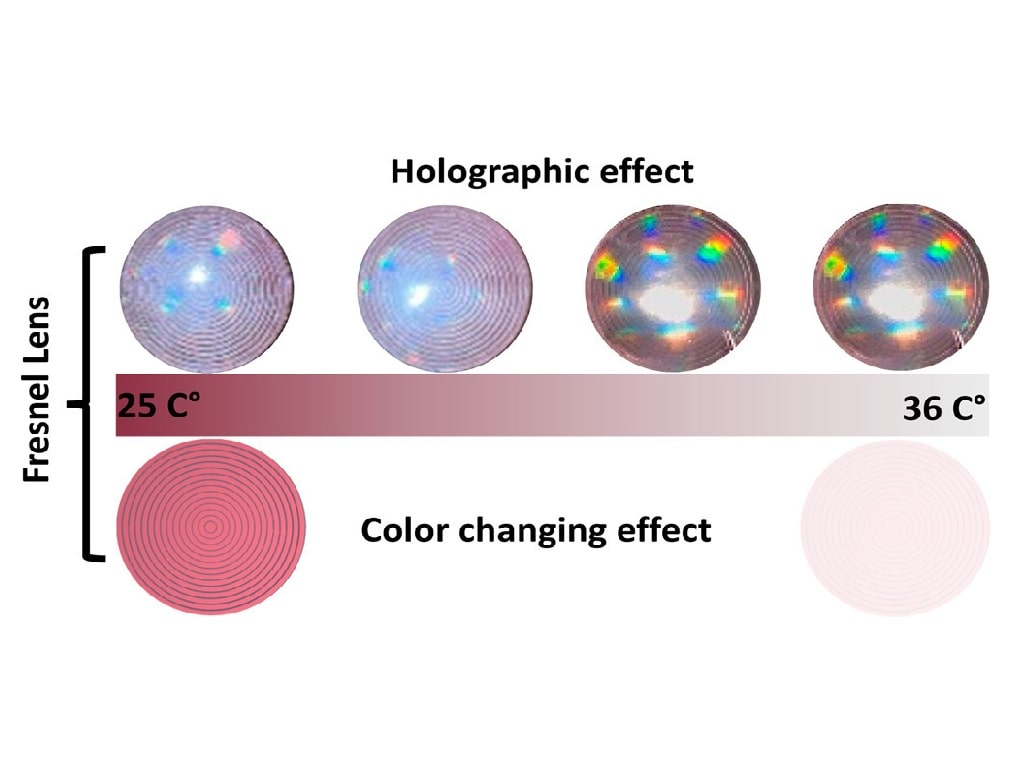

Optical fibers can measure temperature in a variety of ways but the research team chose to focus on the thermochromic method, producing fibers doped with reversible thermochromic powders to show a temperature-dependent optical response.

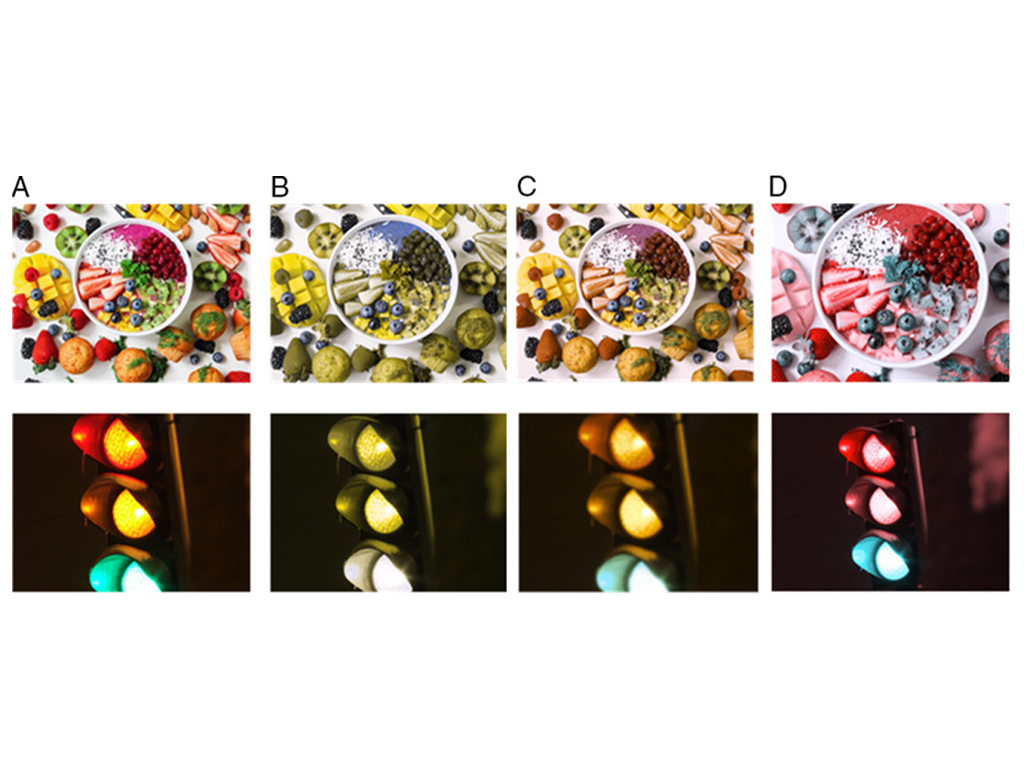

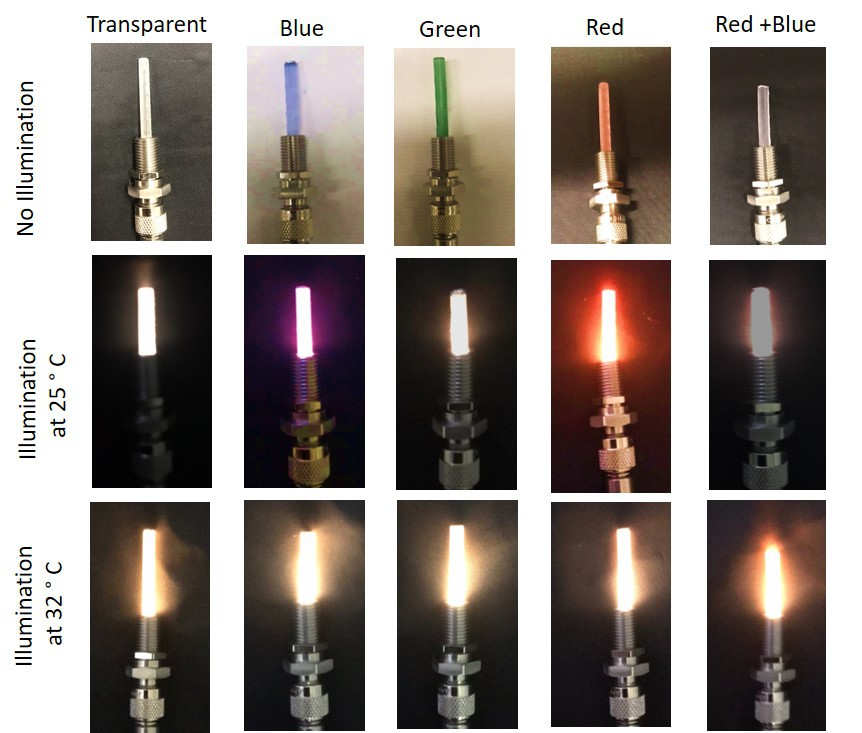

The team prepared resin for the manufacturing process including red, blue and green thermochromic powders and produced five samples: transparent with no powder, a blue/red mix, and one of each single color. The fabricated fibers were flexible and strong, although a reduction in strength was noted in the blue/red mix fiber due to the higher concentration of powders. The team noted the powdered colors were well-distributed through the fiber and no pores were observed between the layers of printed resin, indicating a successful fabrication process.

“We tested the temperature-sensing capabilities by comparing their color transformation with temperature in an open environment,” Dr. Butt said. “At room temperature, all the colors were distinguishable, but at 32 C, all samples turned transparent and were indistinguishable. This effect was reversible as the color came back when the optical fibers were cooled to room temperature again. We did this multiple times to ensure the repeatability and longevity of the thermochromic powders in the fibers.”

While room temperature to 32 degrees is a small operating range compared with the extreme temperatures fiber optics are known to be able to withstand, the research team’s use of additive manufacturing to produce strong fibers that display temperature-sensing capabilities is a step toward developing more robust sensors for further applications.

The research team showed the great potential in sensing applications for 3D-printed stimuli-responsive optical fibers. Multifunctional sensing in 3D-printed optical fibers is expected in the future for targeted biomedical applications, but further testing and development are required.

Jade Sterling

Science Writer

19 September 2022