Khalifa University and Strata Researchers Develop Vision-Guided Cobots for High-Precision Manufacturing Tasks

Project to Offer Numerous Advantages in Performance, Productivity, Efficiency, and Safety, in Line with UAE’s 4th IR and ‘Operation 300bn’ Strategies

Khalifa University today announced researchers at its Aerospace Research and Innovation Center (ARIC) are exploring the deployment of industrial robots guided by computer vision to perform high-precision manufacturing tasks for Strata Manufacturing, in line with the UAE’s 4th IR and the ‘Operation 300bn’ strategies.

These industrial robots, also called vision-guided cobots or collaborative robots, will be used in automated cyber-physical manufacturing and machining processes that will offer numerous advantages in terms of performance, productivity, efficiency, and safety. The aim of this project is to develop things at the lab then deploy them at Strata. These cobots will be used for solving real-world industrial challenges, especially through Khalifa University’s collaboration with the Al Ain-based composite aero-structures manufacturer Strata, which is wholly-owned by Mubadala Investments. ARIC is jointly funded by Khalifa University, Strata, and Mubadala.

At the same time, the project is also building industrial know-how and expanding knowledge base locally through providing students with learning at different stages of their campus life. Two graduate students and four UAE national undergraduate students are also involved in this project. Ameera Al Shehhi, Nouf Al Mesafri, Bushra Al Dhanhani, Mouza Al Zaabi and Anoud Al Zahmi are senior engineering students from Khalifa University who have conducted their summer internship program with Strata. They are currently working on automating repetitive and labor-intensive tasks with advanced computer vision-based technologies that enable robots to operate smarter and safer in the factory.

Dr. Arif Sultan Al Hammadi, Executive Vice-President, Khalifa University, said: “This vision-guided collaborative robots project is another stellar example of Khalifa University’s research projects that are not only industrially-relevant but also economically and financially significant. The outcome of this project will prove beneficial to our partners Strata, through technology enhancements. This project is also in line with the UAE’s 4th IR strategy that aims to work towards advancing the national economy, while making the industrial sector the driving force that contributes to sustainable development.”

This project is among several projects currently being executed at ARIC where researchers from Khalifa University and Engineers at Strata work hand-in-hand to develop groundbreaking solutions for practical problems in advanced manufacturing.

Mr. Ismail Ali Abdulla, CEO of Strata said: “ARIC has a unique model for joint R&D between industry and academia in the whole region. It provides an innovative environment for integrating science and engineering to develop practical solutions in addition to developing human capital know-how that is critical for the growth of the advanced manufacturing industry in UAE.”

The Principal Investigator of the project is Dr. Yahya Zweiri, Associate Professor, Aerospace Engineering, and the Co-PI is Dr. Cesare Stefanini, Professor, Biomedical Engineering, while the lead researcher is Abdulla Ayyad, Research Associate. Strata Engineers Dewald Swart, and Gordon Ferguson are also involved in this project.

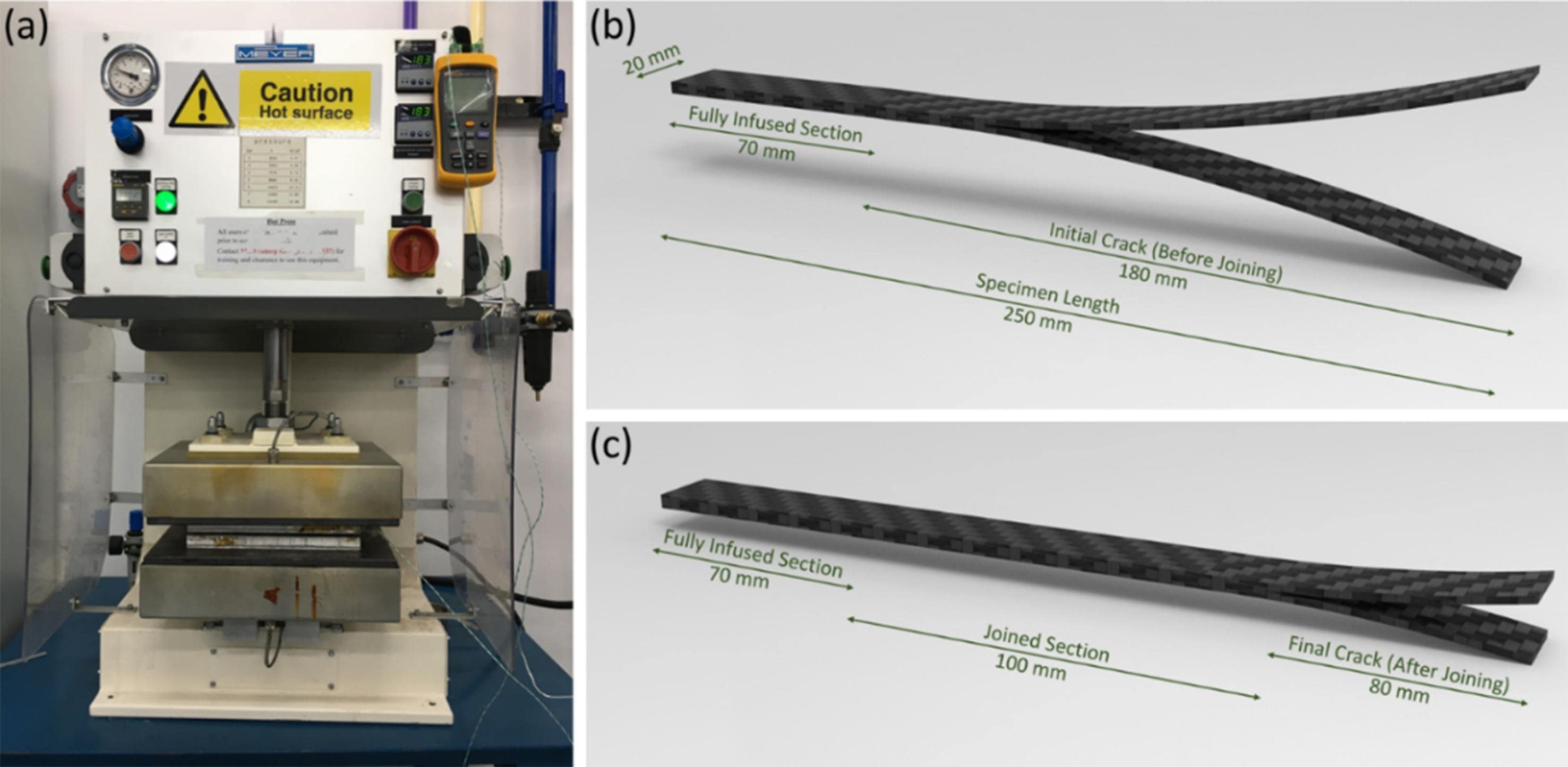

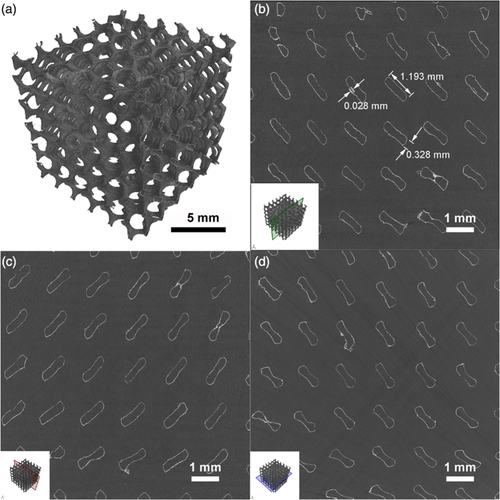

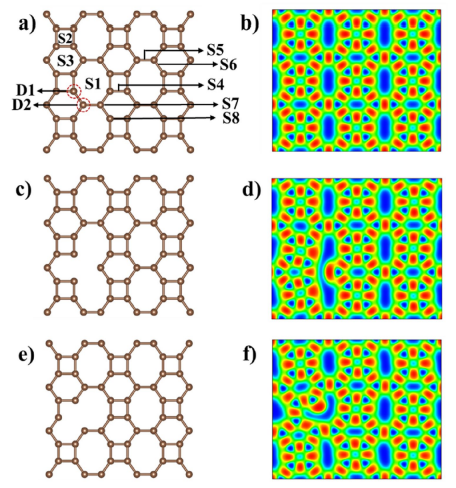

Researchers at ARIC use artificial intelligence and computer vision to develop guidance and control strategies for these industrial robots to perform manufacturing tasks quicker with higher reliability for a wide range of shop-floor applications. In addition, the collaboration with Strata allows validation of these technologies in natural living environments that capture the complexity of the end-use applications.

Concurrently, researchers are also laying the groundwork for the use of vision-based tactile sensing in robotic machining. Tactile sensing is crucial for the success of precise and sensitive machining operations to guarantee repeatability and to avoid damaging delicate work-pieces. It brings advantages in bandwidth, resolution, and cost-efficiency, compared to conventional tactile sensing approaches.

Clarence Michael

English Editor Specialist

11 December 2021