The Geomechanics Lab at Khalifa University is a pivotal research hub that focuses on problems related to subsurface geological phenomena with applications in the energy, infrastructure and environmental sector.

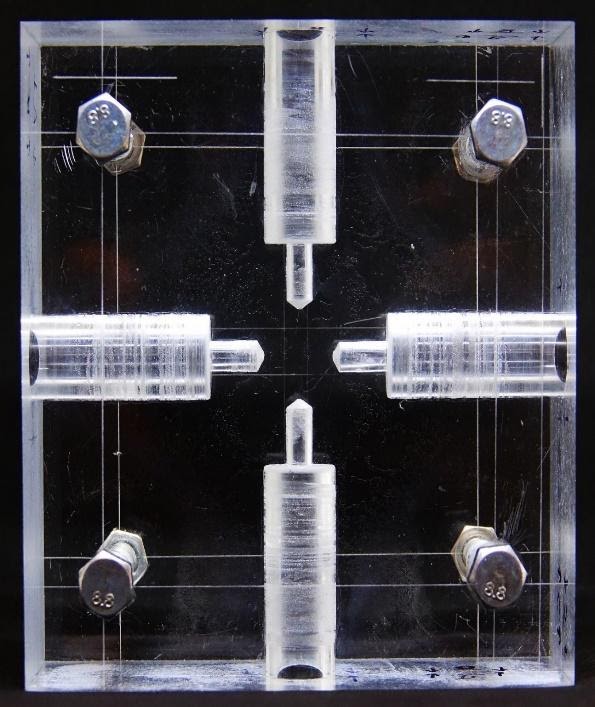

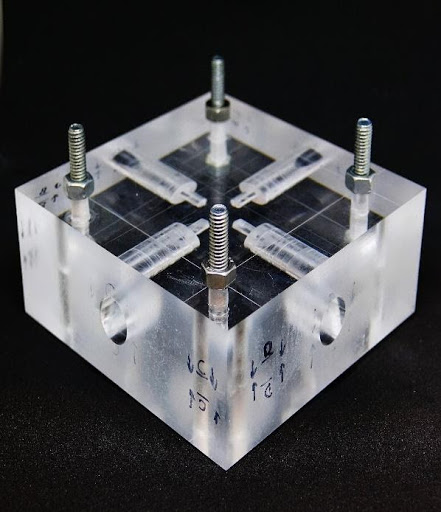

It is one of a handful of labs in the world that are capable of performing controlled lab-scale hydraulic fracturing at reservoir conditions (up to a depth of 9 km) using a whole range of injection fluids from super-critical CO2 to glycerine using a custom built tri-axial testing device (AutoLab 3000; designed at Khalifa University and built by New England Research Inc.).

Experimental and simulation approach to optimize hydraulic fracturing design for unconventional reservoirs.

This ADNOC sponsored project focuses on replicating hydraulic fracturing under reservoir conditions at the lab scale and understanding the influence of different geological factors like the depth of the oil-bearing layer, the orientation of bedding planes, etc. to develop a state-of-the-art computational tool that can be used effectively and accurately in simulating hydraulic fracturing and to improve the process to maximize hydrocarbon production from unconventional reservoirs

AutoLab 3000

This project focuses on enhancing the ability of digital rock physics to predict the mechanical properties and flow properties of carbonate rocks with the goal of creating rock images database at different resolutions from which we can extra all reservoir rock properties.

Images of the 3D solid matrix and pore network structures are taken using micro X-ray tomography (micro-XCT) and nano scale (using FIB/SEM microscopes) and these images are then used to compute

mechanical and flow properties of carbonate rocks. Experimental analysis at different scales are also conducted using Nanoindenters and the AutoLab 1000 rock testing device in the Geomechanics Lab to validate the computational predictions.

FIB–SEM reconstructed volume used for permeability prediction

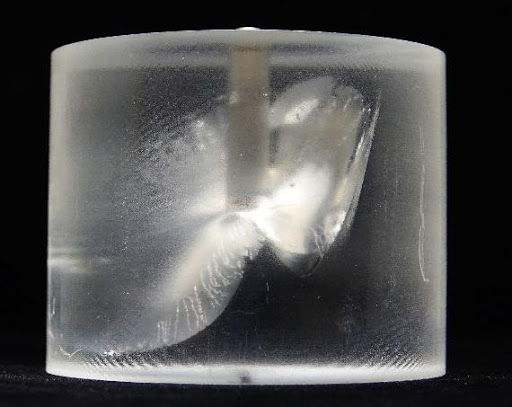

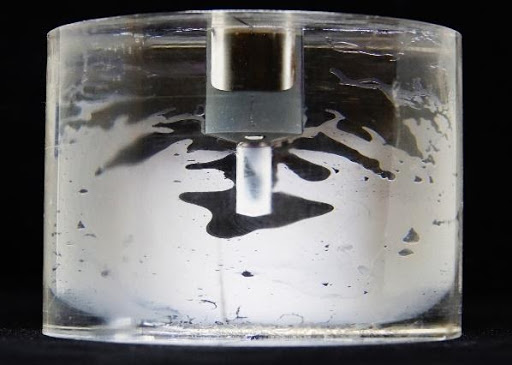

Studying and testing soil and soft rock samples have a lot of applications in the Middle East where cave-ins and wellbore collapses are major issues affecting the energy, construction and urban planning sector.

A significant portion of the cave-ins have been found to occur due to the gradual dissolution of subsurface gypsum layers. The GDSVIS traixial vessel situated at the Geomechanics Lab is used to study the effect of slow dissolution of gypsum samples in real world conditions thus providing valuable data to model cave-ins.

The experimental methodology developed and data generated using this device also contributed to a project that utilized multivariate Gaussian probability distributions to generate probabilistic 3D geologic models, using borehole data model and computer algorithms through Matlab and applied to the case of the Masdar City Subsurface in Abu Dhabi, UAE.

Prepared gypsum sample

Prepared gypsum sample  Soil testing triaxial device (GDSVIS system)

Soil testing triaxial device (GDSVIS system)